Introduction

Troubleshooting and Fixing FPC Thin-Film Key Switch Leakage in Microwave Computers

Microwave computers often experience issues with FPC thin-film key switches due to prolonged exposure to moisture or water erosion. Detecting leakage can be challenging solely based on the appearance of the circuit board. In such cases, it is recommended to clean the film switch, FPC, and computer board with anhydrous alcohol. This article provides insights into resolving this problem, including identifying broken FPC printed lines and conducting necessary inspections for quick fault detection and repair.

FPC thin-film key switches in microwave computers sometimes encounter leakage issues caused by long-term moisture or water erosion. Detecting such leakage can be difficult based solely on the appearance of the circuit board. To address this problem, it is advisable to clean the film switch, FPC, and computer board using anhydrous alcohol. This method has proven to be highly effective in most cases.

In rare instances, the failure of the FPC thin-film key switch may result from multiple broken lines in the FPC printed circuit. However, this type of failure is typically a result of improper maintenance. It is crucial to conduct regular inspections using either the naked eye or a multimeter to quickly identify any faults. If broken lines are detected, they can be easily fixed through re-welding, eliminating the fault.

To fix leakage issues in FPC thin-film key switches of microwave computers, it is essential to address the root cause, which is often long-term moisture or water erosion. Cleaning the film switch, FPC, and computer board with anhydrous alcohol is an effective method for resolving this problem. Additionally, regular inspections using the naked eye or a multimeter can help identify any faults, such as broken FPC printed lines, which can be repaired through re-welding. By following these steps, users can ensure the smooth operation of their microwave computers.

failure of individual key switches on the keyboard. The main cause of the failure is the break line of FPC line or the bad contact of film switch. Can find the corresponding failure of the switch membrane switches, and lines, reference to the above method can be treated after troubleshooting.FPC thin film key switch: Thin Film Key introduction, thin film key is the “Key + film”basic structure, so, the key feel, characteristics and so on depend on the design of thin film key. Considering the reliability of switch contact separation and rebound, the thickness of thin film is 0. – 0.2 mm is the best, too thin springback is weak, contact separation is not sensitive. Thick reaction slow increase the strength of operation. Larger key body, such as the diagonal length of the square key or circular key diameter is greater than, choose 0.15 or 0.2 mm thick film. Thin film slightly thick, strong rebound, the key body after many times after the tendency of the film relaxation is smaller, so as to ensure the normal work contact. When the isolation layer thinner, the substrate film thickness should be thick, thin film easy to occur contact of the self-through. Planar buttons allow the selection of slightly thicker film material, and used for the circuit contact bubble film is Generally 0. MM thick film, only in the bubble ball diameter and the top of the string height of the smaller case, it is appropriate to use thicker film. The membrane button is the necessary structure in the electronic button products, it is the conductive film built in the metal spring sheet button products and the conductive adhesive button products, the function of the membrane button is to play the switch conductive role in the button products, commonly used in PCB and FPC Circuit Board conductive sheet. The structure of the membrane key is very simple. After the key cover and the key cap are taken off, the Membrane Circuit and the circuit board under the key can be seen.

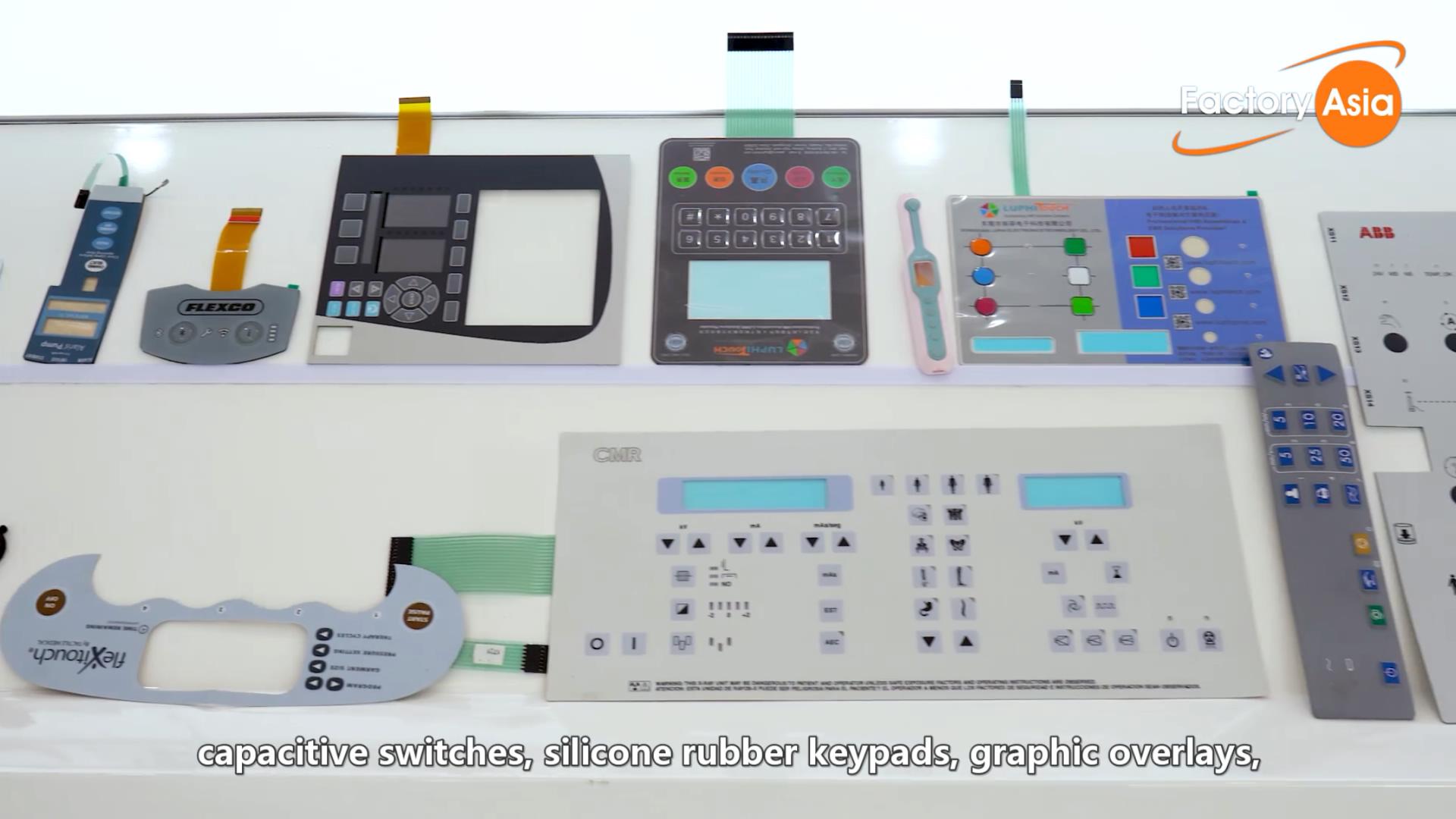

LuPhiTech,a professional OEM manufacturer of user interface subassembly products.LuPhiTech is located in south of China in Dongguan,and since 2008 the core of its business is manufacturing an export of membrane switches & keypads, capacitive switches, silicone Rubbert keypads, graphic overlays, and touchscreen panels. Besides,they also offer mechanical design and PCBA development, as well as development of single-chip solutions, keypad backlighting, and turnkey assembly.

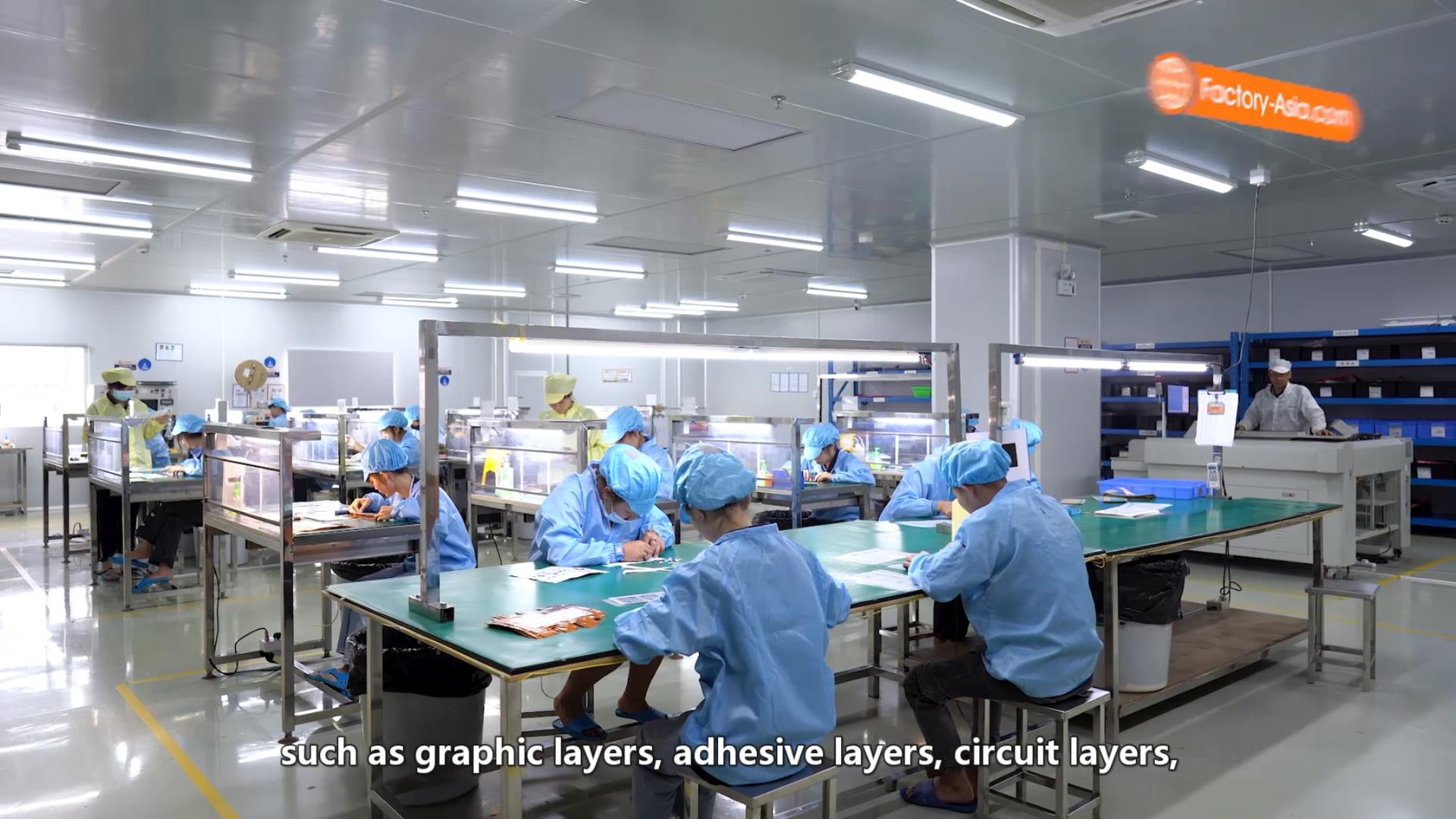

The production of high-tech interface products requires clean and well functioning operations.let’s get to know that how LuPhi complies with industry requirements.

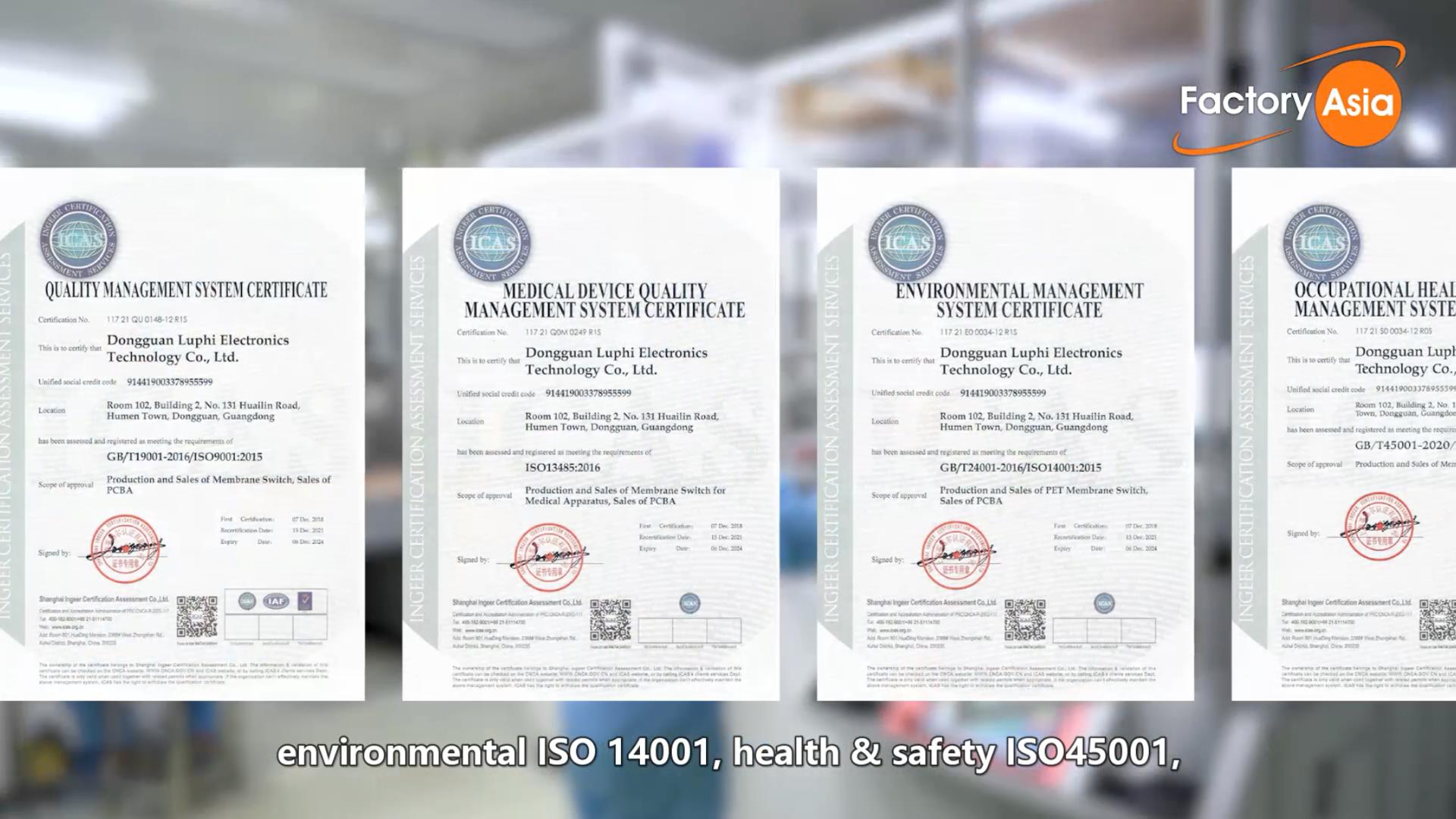

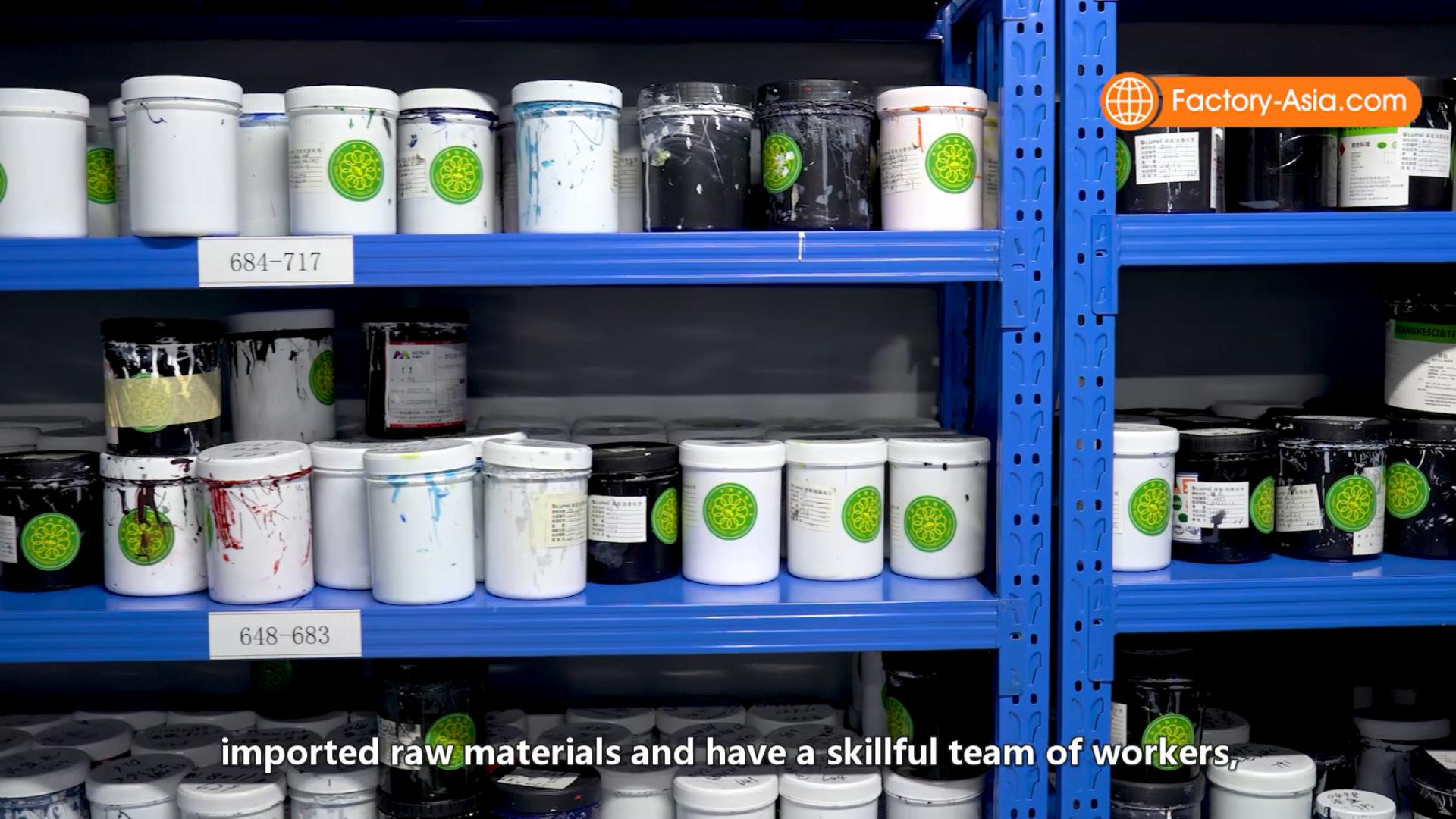

The factory has many strengths-we use high quality imported raw materials and have a skillful team of workers,as well as modern production and testing equipment,our facility is certified with ISO 9001,medical ISO13485,environmental ISO14001,health and safety ISO45001, and the production areas are equipped with 10000 and 1000 class cleanrooms.our products obtain main quality certificates for major markets, such as Europe,North America and Australia.

let’s go to the workshops to see how the products are made!

Design: First,the product concept takes shape in the R&D department,where LuPhi’s engineers design and create initial samples.

before mass production,their PP samples will undergo various function and environmental testing, such as button actuation life testing,high-low temperature constant temperature,and humidity testing,as well as salt-spray & waterproof testing,ink adhesion force testing,click ratio test, and many others.

01 KEY PROCESS OF PRODUCTION

Once the pre-production samples pass all necessary testing and materials arrive at the factory,production begins.LuPhi uses high-quality imported materials, such as 3M adhesive,Autotex polyester,nikomatic connectors, and many other components.

Material Cutting:

The first step of production starts from raw material cutting- where overlay films,circuit films and adhesive layers are cut by automatic cutting machines with high accuracy.

After that,the cut materials are transferred to a silk screen printing workshop,where first the ink is prepared to match the exact color requirements of the customer, and silkscreens are created for printing.

Silkscreen Printing:

Then films and screens are moved to automatic and semi-automatic silk screen printing machines.

Drying:

Following the printing,semi-finished products,are further passed to a baking treatment in a 12-meter drying tunnel until the ink is completely dried and cured, LuPhi also has 4 drying ovens to increase efficiency at this step.

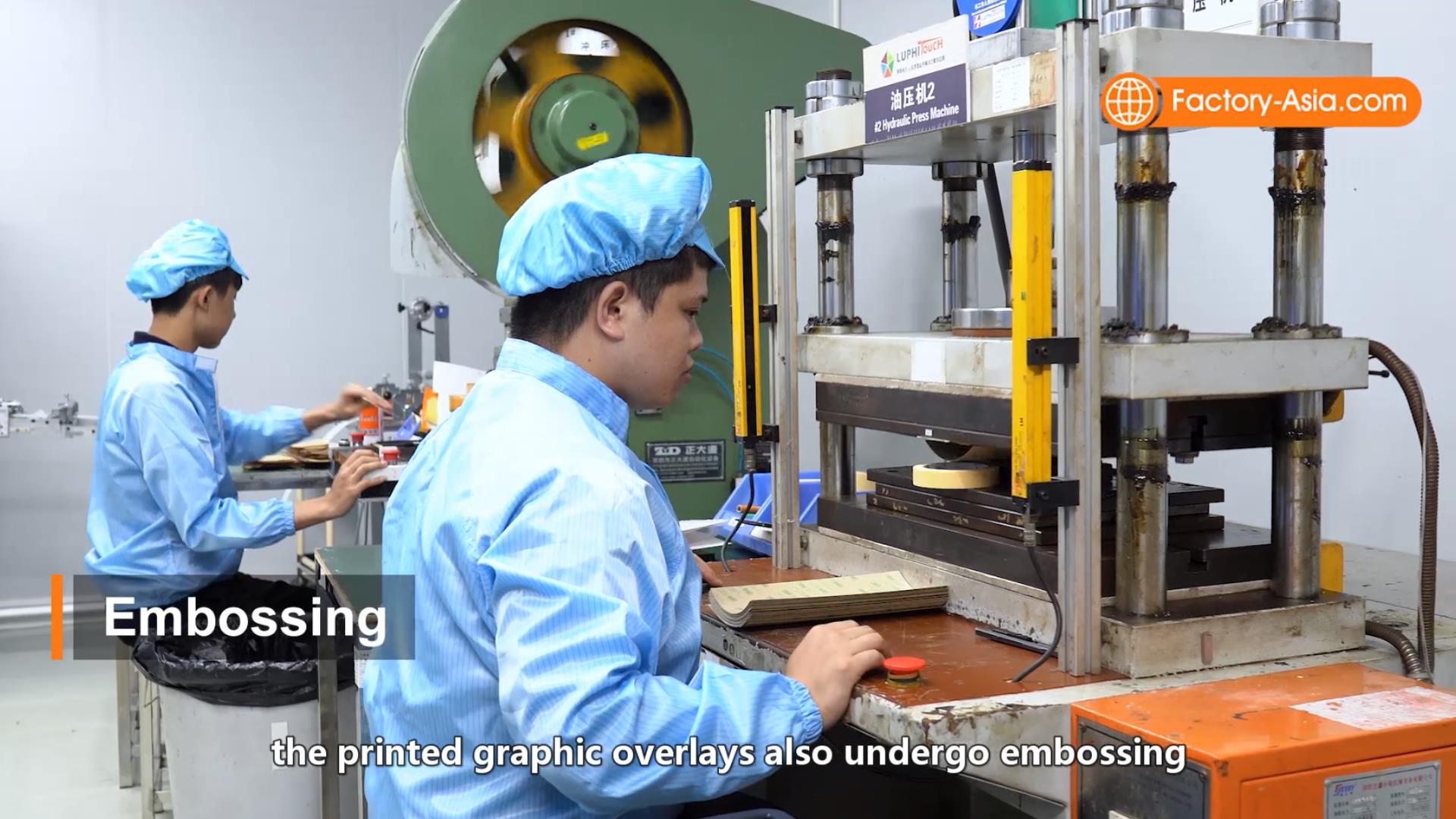

Embossing:

For many membrane switches with embossed buttons,the printed graphic overlays also undergo embossing in semi-automatic embossing machines.

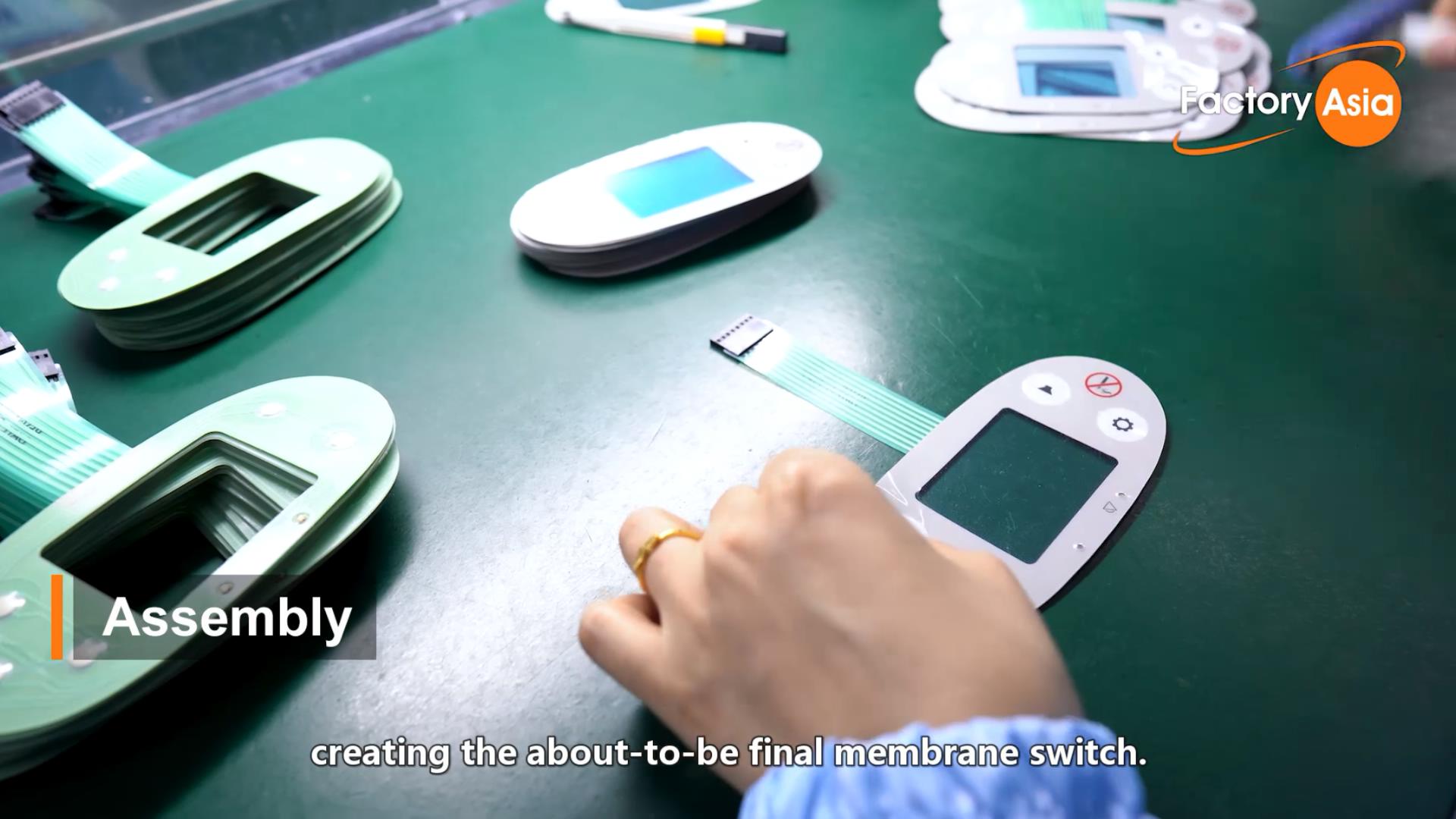

Assembly:

In the end, all layers of the final products, such as graphic layers, adhesive layers, circuit layers and others are assembled and laminated together, creating the about-to-be final membrane switch.

Punching:

After assembly,products are passed to auto die cutting&high accuracy cutting machines to cut out the membrane switch panels and form the final product shape.

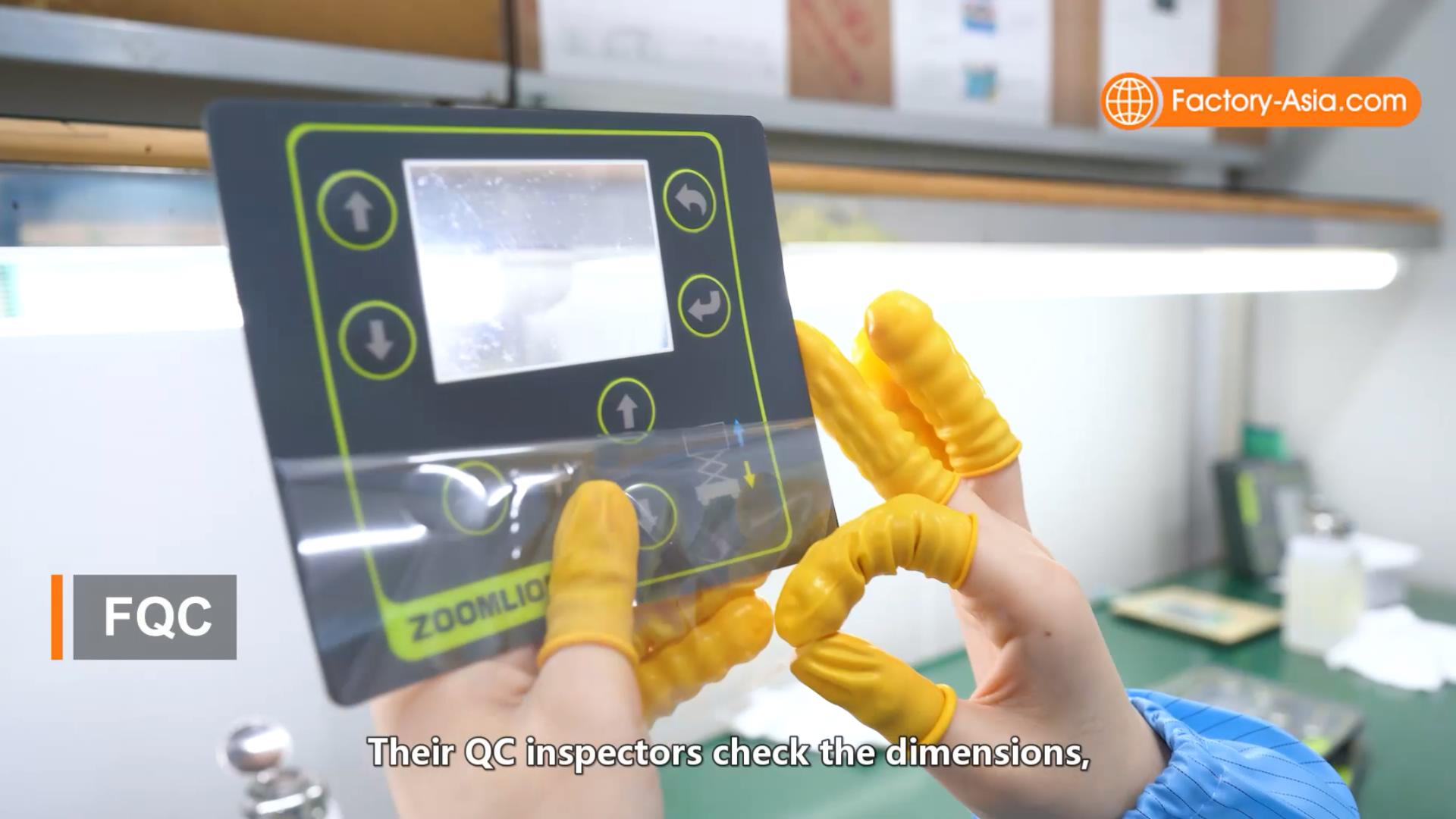

FQC:

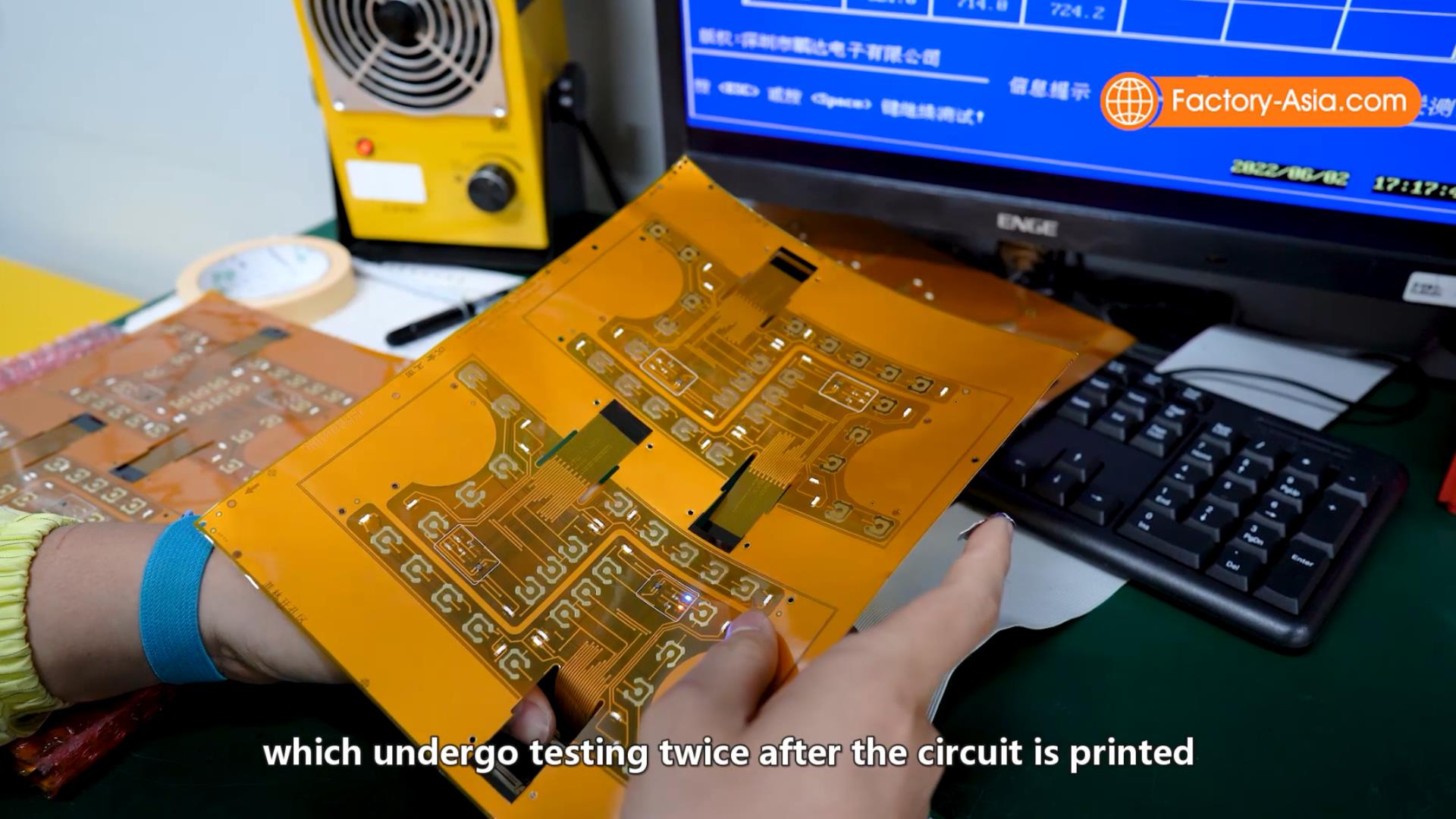

At each production step,products are fully inspected with 100% appearance and function check, to ensure that every product received by customers is qualified.

Our QC inspectors check the dimensions, printings, workmanship and electrical functions, which undergo testing twice after the circuit is printed and assembly is finished.

Packing: Once products pass the inspection, they’ll be cleaned, packed into inner and expert packaging, and shipped to customers all over the world.

02 COMPANY DEVELOPMENT

With our team, about our history and recent achievements:Luphi was established in 2008 for production of human interface products. to support customers from various industries, including automotive, industrial,medical&healthcare industry, household appliances, and others.

over the past year, we achieve a 40% increase in sales through the concerted efforts of the whole team.At the same time, we have straightened the corporate culture, further improve employee satisfaction and happiness index,enhance team cohesion,and laid a solid foundation for the future performance growth.

How are we planning to support the strong demand at the market, in the next couple of years?To support the market demand in customer’s needs,in the next 5 to 10 years,we will increase investment into research and development, and will develop user interface modules for a variety of coffee machines, mixers, vending machines,juicers and other small household appliances.

At the same time,we will continue to strengthen the development and customization ability in high-end application fields,and achieve standardization in middle and low-end needs and customization of high-end needs.

03FACTORY AUDIT, SUMMARY

Now, end of tour to LuPhiTech, These have several advantages of the factory-our facility follows : ISO9001, medical ISO13485,environmental ISO14001, health & safety ISO 45001, and production areas are equipped with 10000 class and 1000 class cleanrooms, that guarantees a clean environment for manufacturing.

Moreover, LuPhiTech uses high-quality imported raw materials and can support the production of quality membrane switches and touchscreen panels in variety of sizes,designs,and functions.Besides that LuPhiTech have a mature quality control system for monitoring in-line and final product quality, with various appearance and function testing.