Explaination For Electrostatic Discharge Shielding

What Is Electrostatic Discharge Shielding?

Person body gains negative electron charges as it interacts with other substances. Once the body is touch of another conductive body, its negative electron should gain positive electron so that it can reach a balance. During this very tiny period, it will discharge electrostatic. We often find that membrane switches has phenomenon of Electrostatic discharge. But also this discharge can have a voltage of up to 15,000 volts (15kV) and a current of up to 30 amps for a brief period.

The delicate ecology of wires and circuits may be severely harmed when a user manipulates a membrane switch. Because the discharge from the user travels to the controller and the delicate electronic components inside. Even though a fraction of a nanosecond is a very tiny period, the levels of ESD are pretty high. Therefore, it only takes a small portion of this transient discharge to seriously harm electronics by causing a circuit to malfunction. To protect their delicate circuitry and components from the ESD arc, membrane switches must be precisely constructed.

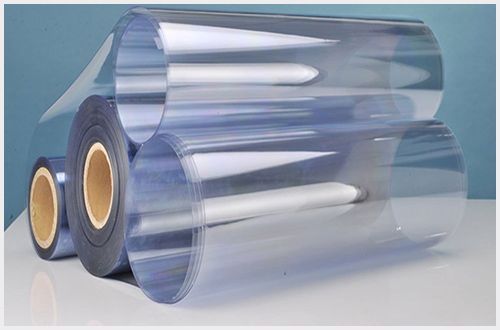

PET Material

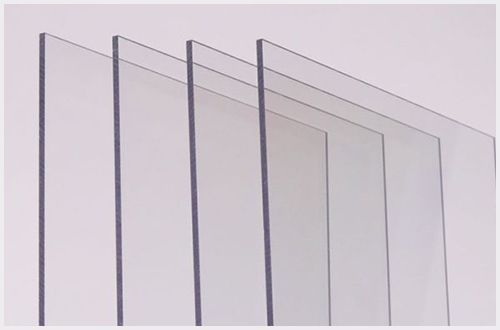

PC Material

Shielding Your Membrane Switch From EDS

An ESD shield is often a layer or several layers of material shielding the membrane switch from discharge.

Applications For Electrostatic Discharge Shielding

You can use various materials to protect your electronic components against EDS.

The material, polyester,

It is widely used and reasonably priced. It is located directly behind the graphic overlay and is relatively thin. The silver screen-printed grid pattern directs the discharge to the chassis ground whenever it comes into contact with ESD.

Aluminum Single Side Coated Foil

The discharge can also be transferred away from the electrical components using a 3-5 mL thin aluminum coating. The conductive side is laid out correctly and directs the ESD through a chassis ground point.

Conductive Copper Mesh Fabric

Due to its higher cost, conductive copper mesh cloth is a high-quality choice only utilized in specific applications. In military and communication units, it is commonly used. Additionally, components will be shielded from electromagnetic interference (EMI) and radio frequency interference (RFI) by a single layer of copper mesh fabric (RFI).

Indium Tin Oxide (ITO)

When a display needs to be protected against electrostatic discharge, it is covered in indium tin oxide (ITO), a transparent, polymeric polyester substance that is clear and electrically conductive. Although more expensive and complex to construct, it will shield the display area from ESD, EMI, and RFI.

How EDS Shielding Works for Membrane Switches

ESD has two ways of penetrating switch circuitry: it flashes around and between the circuitry’s protective layers or punches through the layers directly above the circuitry.

A few dielectric barrier layers, such as a graphic overlay (made of polyester and measuring 0.006″-0.007″ thick). Top pressure-sensitive adhesive, and a dome retainer (made of polyester and measuring 3-5 mil thick), can be added to the top of the membrane switch interface to help shield it. Typically, this is a reliable ESD barrier with a 2 kV/0.001″ thickness rating.

To cut through top layers, ESD would need to have a voltage more significant than the material’s dielectric strength, expressed in volts (V) per unit thickness. The point at which ESD breaks down must be higher than 14 kV if the insulating material for the plastic overlay material is 0.007″ thick and has a dielectric strength of 2 kV per mil.

To reduce the ESD arc that reaches the circuitry by flashing around and between the membrane switch layers. We adhere to certain best practices, such as placing a gasket around the switch or moving the traces as far away from the edge of the keypad as possible. Allowing the first and last contacts of the connector to make contact with an earth-grounded loop on the edge of the circuit layer far from any circuit traces is a practical, affordable solution if edge distance is a concern.

LuphiTouch offers best-practice input to our customer’s design to shield the electrical components inside membrane switches from electrostatic discharge. Email Us today, and get your solutions.