Capacitive Touch Panel

Capacitive Touch Panel

The main components of a capacitive touch screen are transparent touch panel, touch circuit,IC chip, touch control board and Led patch light

Touch panel

The cover window (usually called “cover panel”) is mechanical protection and a decorative element of the entire module. In most cases, the manufacturers use transparent material to make the cover window The typical protective layer thickness is: 1.5-2.5 mm.

For plastic material , we select transparent acrylic panel with 1.8-2.5mm in thickness as cover panel for the capacitive touch panel. on rear side, number, letter and windows can be printed or by laser. With backlighting condition, the letter and number looks more clear. This is top layer, as an operation interface for user, which is made from anti-electrostatic shielding material.

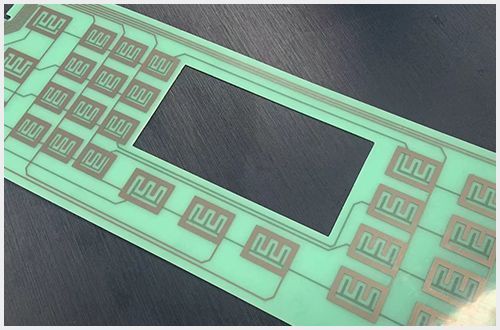

Touch circuit layer

This layer is made of FPC printed circuit layer, print conductive ink onto PET or PC substrate. Definely, it should have a termimal connection plug connected to the CTP mainboard. Its touch position must correspond to all positions for IC sensors on the CTP control board so that realize control functions for the capacitive touch panel.

All touch points for the touch circuit layer , are communicated with IC sensors chip. When you touch one of any touch point, trigger a singal, it will transit the singal to designated IC sensor. IC sensor receive the singal, transform the singal to order, and have a right execution. The touch circuit layer is sensitive layer, which is capacitive sensitive control functions, regardless of thickness of touch panel.

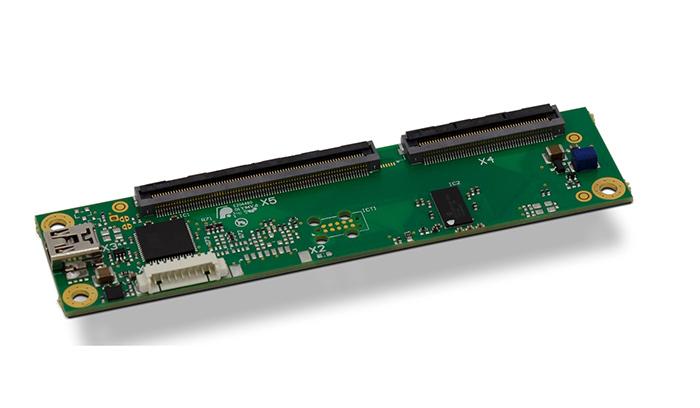

CTP control board

The sensor ends with electrodes-electrode data that you need to collect and manage from the controller.

These touch sensors are positioned and welded on the CTP contol board, insert special programme to these capacitive sensor, and control sensitivity of their touch , to control a special device and machine actions. Of course its function depends on what functions end customer need to control special device and equipment. Its function is complex due to these IC sensors chips are all control by codes programme. For example, it finish timer setting, music embeded, circuit strong and weak, temperature setting, mechanical actions etc. So it is custom touch control panel, is so flexiable.

The choice of the controller should be in accord with the application of the module and the environment that you plan to use. Therefore, it is important to consider a number of factors. The first step is communication-you need to set up the touch panel.

Next, the size and the efficiency and safety of the control board should be considered. In this case, electromagnetic compatibility (and therefore electrostatic discharge and radiation sensitivity) should be analyzed.

The IC can perform various functions that should meet the requirements of the application. You can find ICs suitable for water performance or salt water environments, as well as ICs that support gloves and special gestures.

The LUPHITOUCH offers outstanding quality Touch Capacitive Control Panel. Our standard controller supports coverslips up to 2 mm. Although we are familiar with the technology that supports protective cover up to 5 mm thick.