FPC and PCB Membrane Switches

FPC and PCB Membrane Switches

Difference of FPC and PCB Membrane Switches

The circuit of membrane switch can be flexible or rigid. It depends on the customer end application and is also related to the cost budget and other considerations. For example, life, resistance, connection type on the mainboard, etc.

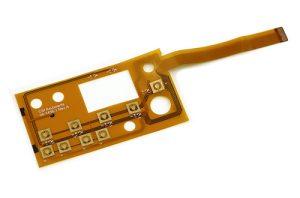

Circuit Types for membrane switches, there are two ones. They are FPC and PCB membrane switches. FPC membrane switches’ circuits are silver-printed PET circuits, while PCB membrane switches’ circuit are copper etched PCB circuits. Their difference and advantages & disadvantages are listed below:

| Items | Silver Printed Circuit FPC | Copper Etched Circuit PCB |

| Material | PET (Polyester) | Polyster coated with copper |

| Conductor | Printed silver | Copper |

| Contact Fingers | Copper and Carbon | Gold plated Copper |

| Contact Buttons | Stainless Steel | gold plated stainless steel |

| Life & Reliability | normal | good |

| Stability | normal | good |

| Resistance | low | Very low |

| Cost | low | high |

| Lead Time | 2-3 days | 7-10 days |

| Pitch | 0.5mm, 1.0mm, 1.27mm, 2.54mm | 0.5mm, 1.0mm, 1.27mm, 2.54mm |

Usually, if the membrane switch needs to assemble many LEDs, we promise our customer to have a good solution for their membrane switch. Whenever you use any kind of circuit board, we can design the circuit and also get more stable LED soldering quality.

For PET circuit , which is more economical. In addition, the contact fingers pitch commonly depends on applications and features of membrane switches. As such circuit for membrane swith, its stability is normal, service life is shorter , compare with Rigid PCB circuit’s membrane switch, too.

For the Rigid circuit membrane switches, the circuit is the rigid printed circuit board. The material of rigid PCB is usually FR4 and Copper. By this type of membrane switch, the connector usually is the SMD connector(sometimes also can be straight through connector). For some applications that need a very stiff requirement, then use a PCB circuit’s membrane switch.

Terminal connection to FPC and PCB Circuits Layer

Traditionally, our FPC membrane switches circuit layer terminal connection is sealed by temperature, which to connected with electric circuit layer as a whole. Such kind of application, then the Hotbar lamination (or called pulse hot press lamination, or heat seal lamination).But also there is an exit slot for terminal connection strip left. If customer have an additional requirement, to have some special functions for water proof and damp involved, we often suggest such circuit layer can add a water proof washer.Like this , our membrane switches will have more longer service time. Whenever PCB or FPC circuit.

In another one, some of customer need seperate terminal connection slip from mainboard, they don’t like that membrane switches with terminal connection slip as a whole. Oppositely, they want to single mainboard and another terminal connection slip separately. Then We suggest you can choose PCB board circuit layer. Although its cost is little higher, it will can meet your special demands ! We can be sure that the terminal connection slip is seperated from circuit board completely, which is with in-built pin finger socket on the mainboard as well !

LUPHITOUCH is a professional manufacturer with such kind of lamination capability. We have such kind of assembly machine. We can process various kinds of membrane switch, with FPC and PCB membrane switches are vailable !

If you want to know more about our FPC and PCB circuit membrane switches services, please feel free to contact us.