Membrane-switches-total-solutions

Membrane-switches-total-solutions

membrane-switches-total-solutions, includes of capability of engineering and design for membrane switches, rapid prototype , PCB Assembly, and custom user interface . We are an emerging high-tech company dedicated to solving the most difficult interface problems of our customers. This has promoted the innovation of switches, and our engineers have developed several proprietary technologies to make our keyboards quieter, brighter, stronger, and more affordable.

Engineering & Design Membrane Switches

Large organizations around the world rely on us to obtain a large number of custom user interface technology custom membrane switches, graphic overlays, and rubber keyboards. Other engineering-based solutions include functional die-cutting, control panel components, and laser engraving ect.

The reason is as follows: Our professional engineering and design team services are an essential part of successful product development and manufacturing. From prototype to all manufacturing stages, our skilled in-house engineers and technical graphic designers will collabrate with you every step of the way from prototype through all manufacturing stages.

Our engineering and design team will provide professional knowledge to guide you through the entire development phase to complete the final design. Our team provides the following assistance:

- Material selection, artwork, and color matching

- Durability options

- Embossing

- Faceplate options

- Tactile versus non-tactile

- Domes and actuation

- LEDs/backlighting

- Adhesives

- Shielding

- Sealing/gasket sealing

- Rapid prototyping

- functions testing

Rapid Prototype Process membrane switch

Testing and re-testing the design is a key step in the development of smart innovative products. Rapid prototype process allows product calibration early in the process, thereby reducing development time. By allowing stakeholders in the engineering, manufacturing, marketing, and purchasing departments to view the product early in the design process, enhancements can be discovered, changes can be made, and errors can be corrected-quickly and cheaply.

Our rapid prototype and manufacturing process can increase product variation, increase product complexity, extend product life, and shorten delivery time.

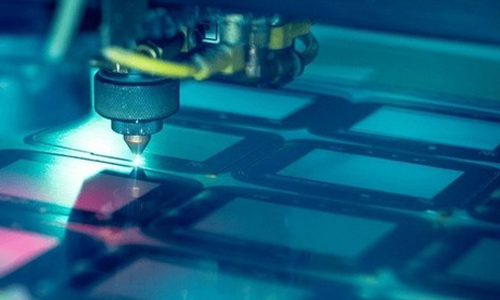

In order to achieve rapid prototyping, we rely on laser tools and digital printing technology instead of fixed tools and screen printing. These simplified processes greatly reduce the lead time required to manufacture physical prototype parts. LUPHITOUCH’s rapid prototyping service supports product development for graphic overlays and custom plastic labels.

- Significantly reduce lead times for part prototypes

- Decrease product design/development time

- Eliminate costly mistakes

- Minimize engineering changes

- Eliminate redundant features early in the design

- Extend product lifetime by adding necessary features

Value-added Services / Assembly

From the circuit design to the final assembly of the sub-panel, LUPHITOUCH provides all the components to provide a complete turnkey product while maintaining quality and timely delivery at a competitive price.

We have established long-term supply relationships with reliable subcontractors who can provide quality parts at competitive prices in a timely manner. In addition, if you purchase and purchase a customized component, we will receive the component and assemble it into a “customer-supplied product”.

When used with LUPHITOUCH for custom assembly, you can achieve the following advantages:

- Experienced design and engineering from product development to production.

- Environmental engineering solutions.

- Innovative solutions for product engineering and effective cost control.

- U.S. and offshore manufacturing production facilities.

- Perform inspections in all processes, including zero defect certification caused by incoming goods.

- Fast, fully functional prototype.

- The lead time is short, and there are documents to prove that it can be delivered in time.

Purchasing sub-components to LUPHITOUCH can reduce costs related to:

- Processing related to receiving, inspection, storage, assembly and invoicing.

- Paperwork required to manage purchase orders and quotes.

- Possible errors and omissions when processing multiple quotations and purchase orders.

- Inventory list.

- Processing shortage, scrap, over-shipment and scrap.

- Processing, receiving, inventory tracking and other accounting duties.

If you want to know more about our solutions, please feel free to contact us.