Backer Membrane Switch – What are They and What do They do?

Composition and Functions of Backer Membrane Switch

Let us learn about Backer Membrane Switch. A membrane switch is a user interface or transitory electrical ON/ OFF switch, which activates and deactivates a device through a circuit. Industrialists use membrane switches due to their multi-coloured designs, limitless sizes, and shapes. They are also low-cost replacements to PCB manufacture.

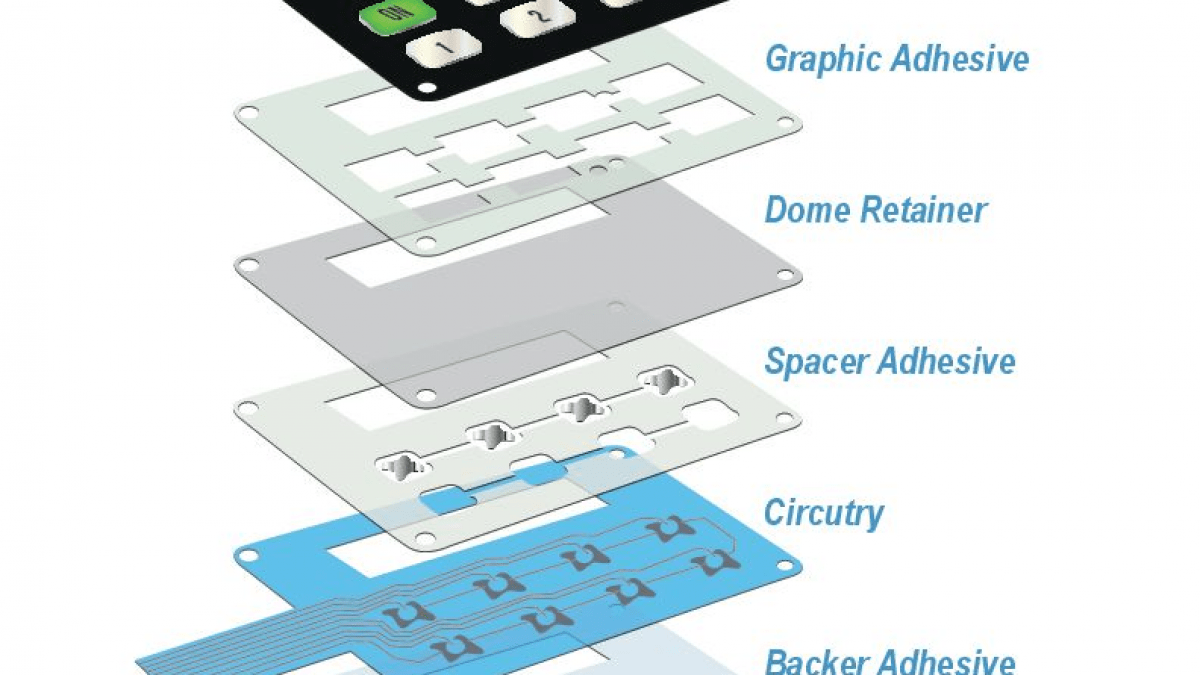

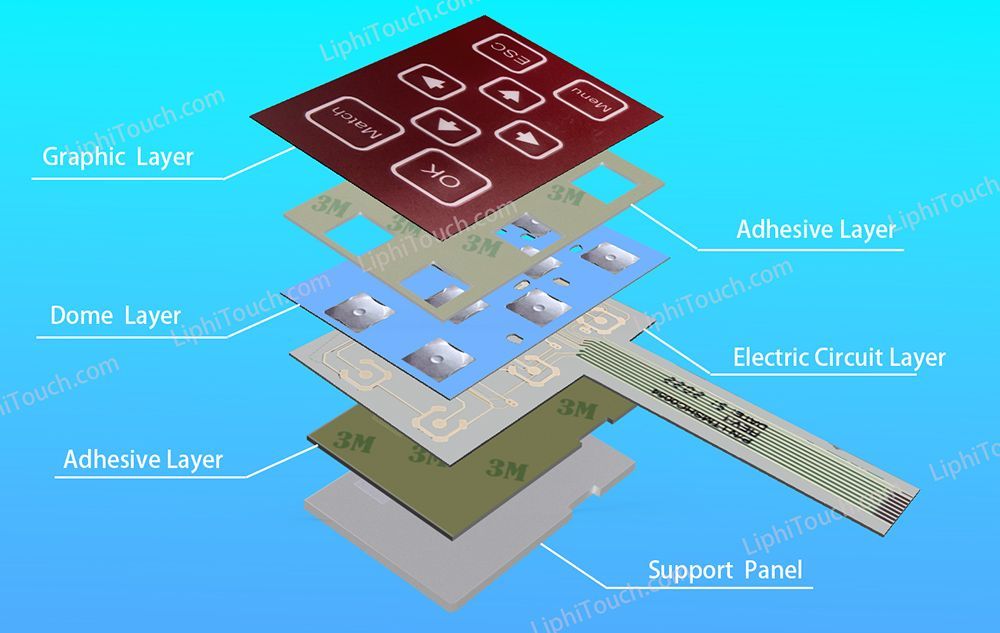

What brings durability and flexibility in a membrane switch and what makes it a robust solution? One of the key strengths of a membrane switch is the ease of its components. In addition, a membrane switch typically integrates flexible layers packed together in a hierarchy. These layers are graphic overlay, overlay adhesive, upper circuit layer, or dome retainer.

Below them is a spacing layer, lower circuit layer, rear adhesive layer, and lastly, rigid support layer or backer .When stimulated, all these layers interact with each other from top-down. The rigid support layer is an optional layer.

In today’s aggressively competitive environment, unusual products put themselves apart.

Therefore, a membrane switch is a perfect solution, which quickly and economically delivers a reliable output. According to expert manufacturers, all the membrane switch components work together to form a reliable human-machine interface.

In addition, a membrane switch should essentially comprise a membrane layer and a static layer. The static layer does not become static characteristically without bonding permanently to the instrument housing.

Need for a Backer Membrane Switch

Characteristically, a backer is a form of the rigid substrate to which the rear surface of the membrane switch attaches. It is also the final part of the membrane switch. It usually incorporates an adhesive serving the basic purpose of bonding it with the substrate. Most of the membrane switches need a rigid or strong support layer or a backer.

The backer provides supplementary structural support to a membrane switch assembly and increases its structural reliability. Together with the combination of backer, a membrane switch assembles forms the shape of a membrane switch panel. Also, the need for this backer is evident in that it enables the user to activate the switch conveniently while pushing against something.

The useful features of backer range from providing structural support to the membrane switch to safeguard it from moisture and rusty environment. Moreover, an ideal backer takes the shape according to the materials, surface, the performance needed, and appearance, etc. It is capable of adapting to the surface of the application.

Physical Structure of Backers and Their Applications

Choosing a backer for any membrane doesn’t exactly serve the purpose. But when the manufacturers realise that backer’s job is to provide a tensile strength to the membrane switch, they develop impressive backer designs.

Considering the type of application, the backer of the membrane switch requires a different range of materials. The designers manufacture the backer with stand-offs, holes, and studs to suit the application. However, the important thing is that the activation of the switch works in the best manner with no bumps or unlevelled surfaces.

That is why the physical structure of the backer of the membrane switch is plain or flat to the maximum. The physical properties of a backer make it stronger enough to withstand external conditions including heat and humidity etc.

The state-of-art technology used in the manufacturing of such backers enhances their capacity to back membrane switches. In addition, the fabrication capability of the backer eliminates the connected price increase of a subcontracting process. As a result, it reduces the manufacturing cost of the membrane switch assembly. As stated above, the manufacturers also apply different types of materials in backer membrane switch suiting the application.

Aluminum Backer

The most common material for the backer is aluminum, which is available in a range of installed hardware. Aluminum may be painted, bare, chemically treated, alodine, or anodize. This type of backer is lightweight and durable. In addition, it is highly cost-effective and gives unparalleled versatility to the membrane switch. Manufacturers prefer aluminum backer because it backs designs such as painting on top.

Aluminum backer membrane switches perform the functions of playback switch, change-over switch, control switch, and sometimes disconnector. These backers get their place mostly in membrane switch applications for home appliances.

Some manufacturers offer black anodize aluminum backer-based membrane switches and keypads to meet the varying demands of the customers. Switch applications in aerospace industries, agricultural machinery, measuring instruments, networking, telecommunication, and marine industries require these backers.

Plastic Injected Molded Backer

This type of backers contains molded cavity which connects with the membrane switch and lets it level against the case surface. Plastic injected backer is common in membrane switch applications in medical equipment.

Their main advantage is that they possess nearly identical texture and colour. This texture matches the membrane switch and the whole component of membrane switch assembly appears as a single piece. The injector pin marks, bosses, and parting lines do not integrate into plastic injected bakers in order to avoid switch actuation problems.

Steel or Metal Backers

The metal backer membrane switches are more popular with industrial membrane switch applications. They typically comprise steel or aluminum alloys. Generally, such backers have coatings with a protective finish to avoid rust and corrosion issues. If rust develops on backers it can easily weaken the membrane switch and all the electrical components in it.

In order to avoid steel backers getting rust, the membrane switch manufacturers apply the anti-corrosion material chromium to the backers. Just a small amount of chromium transforms the metal into stainless steel and protects the backer from rust. Therefore, the most common metal backers for membrane switches are black anodize aluminum backers. They can take any size, shape, or depth depending upon the membrane’s requirement.

Metal backers have used in LED touch screen membrane switches. Such screens have wide usage in the automotive industry, POS terminals, medical equipment, industrial control units, mobile manufacturing, and factory automation.

Some industrialists also offer customized polymid FPC membrane switches with a metal backer to cater to the demand of almost similar industries mentioned above.

Winding-up Discussion

Support is always crucial when somebody wants to operate the membrane switch smoothly. The backer membrane switch presents an inflexible platform for unattached membrane switch assemblies.

Usually comprising a metal frame such as aluminum or steel etc. it improves the functional capacity of the membrane switch. Therefore, choosing a backer is not a light decision to make. Your choice will also play an important role in the quality of the membrane switch.

If you wish to buy a membrane switch from the market, always ask the supplier if there is a backer to which the membrane switch applies. If not, ask the manufacturer to backer the integrated membrane switch.

It will make your substrate a complete product and you can conveniently install it in the finished product. The backer should be as flat as possible. A bumpless backer can positively affect the performance of the membrane switch. Inversely, it may lead the switch to activate allowing the liquid to seep in.

In order to learn more, visit our website.