Choosing a good membrane keypad manufacturer will decide the quality of products can be sure so that your customer will trust you. Can Membrane switches be recycled? Today as the technology has evolved to make latest and advanced applications. The membrane keypad manufacturers are also producing extra creative and modern products to face all these latest trends. Actually, they have understood how to face all these increasing and ever-advancing technology demands. So, they are continuously blending expertise solutions with extra touch of creativity and innovations. Moreover, they have proved their abilities by their best quality products which are equipped with all functional and aesthetic needs. They are producing hundreds of millions of membrane keypads every year which are feeding countless requirements of electronic business. In fact, the membrane keypads are playing vital role in all multiple electronic industries. It doesn’t matter that how electronic gadgets have become extra modern and complex in this technological era. Because membrane keypad manufacturers deeply know how to produce ideal solutions for all these growing variety of applications. Today we are here to explain that what are these membrane keypads and their popular types. Further, their advantageous applications and how they are beneficial in extreme weather conditions. Simultaneously, we will also describe 8 most important considerations which you should focus before selecting best manufacturers of membrane keypads.  So, let’s begin!

So, let’s begin!

What are membrane keypads?

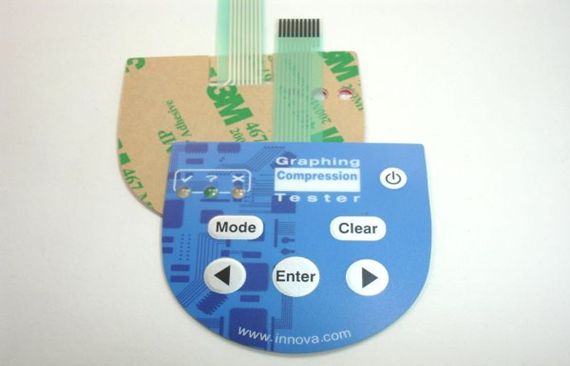

Basically, a membrane keypad is a kind of special device for electronic sensitive touch. We use it for numeric input which even can work on low voltage with the help of a small PCB board. Moreover, a membrane keypad consists of a special backlit on its surface which completely covers its top area. This backlit helps to save it from,

- debris;

- moisture;

- and several other dust particles, etc.

The membrane keypads and switches have commonly found in all modern industrial and commercial areas. The membrane keypad manufacturers are rapidly producing these switches and keypads for all your ease and multiple uses. These keypads execute the command when you put some pressure on their buttons. Actually, the electric connection which works during pressure breaks down when you remove the pressure. Several other keypads usually contain plastic pieces and copper for conductivity. But membrane keypads use PCB boards in their base. Furthermore, these keyboards go on the front of devices where you can easily access them.

4 most popular membrane keypads which membrane keypad manufacturers produce

Generally, there are 4 most popular types of membrane keypads which manufacturers produce. Each of them also has different designs. All of their designs have different tactile. Moreover, each design has different structure in the base. The membrane keypad manufacturers also use many different materials to construct these keypads. Actually, they select best materials according to the needs of these keypads.

- Nontactile

- Metal dome tactile

- Domed graphic tactile

- Plastic tactile.

Number of layers in membrane keypads

When you hire a best professional team of manufacturers, they will provide you two options in selecting layers. Moreover, they use PTF (Polymer Thick Film) to make ideal bases of membrane keypads. In first option, they can provide you, A membrane layer: This membrane layer actually contains,

- a shorting pad;

- a printed circuit board;

- and at least one necessary switch pole.

A static layer: Basically, this is a supportive layer which consists,

- a shorting pad

- one switch pole.

Furthermore, in the second option, membrane keypad manufacturers use two or more than two metal insulating layers. Hence, they can provide you, The rigid metal layer: This layer supports the flexible static layer as its backing. The tactile layer: This layer actually provides a tactile effect. The graphic layer: on this layer, manufacturers screen the print graphics or decoration, such as,

- letter;

- numbers and symbols, etc.

What are 5 exceptional advantages of membrane keyboards and switches?

Although there are countless benefits of using membrane keypads in many applications. As well as nowadays they have become most popular for their maximum helpful uses. Here we are describing some exceptional advantages of membrane keypads which you can easily get from membrane keypad manufacturers. For example,

- membrane keyboards are more affordable, low cost and effective;

- these keypads have extremely versatile designs;

- they are very reliable;

- membrane keypads actually have much lower conductivity in comparison to others;

- these keypads are ideal choice for several different low-power applications.

What are the best applications of membrane keypads?

Nowadays electronics designers are increasingly using membrane keypads for making their electronic products more innovative. Further, they are extremely helpful in several devices. Some of these are,

- All industrial instruments

- Medical tools and equipment

- Automotive instruments

- Agriculture tools

- Testing devices

- Safes

- Helpful household gadgets and appliances.

Important considerations before choosing reliable membrane keypad manufacturers

Basically, it is really important for you to select ideal membrane keypad manufacturers for getting best quality products. Because for successful business you really need to hire ideal manufacturers. So, you should make following considerations when you want to get ideal products. Such as,

- Always prefer those manufacturers which have experience of at least 10 years of excellence

- They also can provide you competitive prices along with highly first-class services

- Always prefer the professionals for the production of your massive projects

- Their highly trained personnel must have ability to provide you only the best

- They should have all the necessary certifications from several famous certified agencies, like;

- They should deeply concentrate to your raw ideas for producing highly precise final products

- Make sure that your membrane keypad manufacturers have ability to provide you the products which have,

- perfect appearance

- best lighting

- good texture for all of your products in bulk production.

- They should also support your designs from early rapid prototyping to final production

Why membrane keypad manufacturers produce weather resistant keypads?

If we peep in the decade of 1980, we will find that at first membrane keypads were not as reliable as they are currently. But membrane keypad manufacturers have tried hard to develop quick and error-free keypads at reliable prices. Hence, today the modern membrane keypads have ability to provide you best protection with great versatility. At first these keypads were not resistant to the following,

- liquid;

- moisture;

- and several other dust particles.

Moreover, they got damage because moisture and liquid penetrated into their holes or lines. But the latest membrane keypads are an ideal alternative to those old and hardware keypads. The latest membrane keypads have designed by using polycarbonate film on their surfaces. Membrane keypad manufacturers have used this film as it has great power to resist any type of liquid and moisture. It often happens that you accidently drop coffee, tea, juices or some other liquids on your membrane keypads. Modern membrane keypads have ability to provide best protection from all kinds of chemical and moisture. Further, these keypads are best choice to use in any season like, in rain or fog. The manufacturers have produced these keypads to help you in any kind of weather whether it is,

- rainy;

- stormy;

- or fogy.

Conclusion:

In the above guide, we have tried to give you all basic information about membrane keypads. Moreover, we have also guided you to select ideal services from good keypad manufacturers. Your selected manufacturers must have capability to provide you most complete and best line of high-tech printed components. Furthermore, their team includes highly qualified engineers. These engineers have best experience of at least 10 years of working. So, they make sure to provide you the best solutions of all problems of their customers.