As a membrane switch, which is either convenience or safety when you selected it to control a precision instrument and device. Of course it can also impress you deely for its functions and features , it can travel some of automation actions and operation steps. Then some one ask like this, “how long do it last ? “ With statistic from laboratory show that, it has a 10 year life span lasting in normal environment.

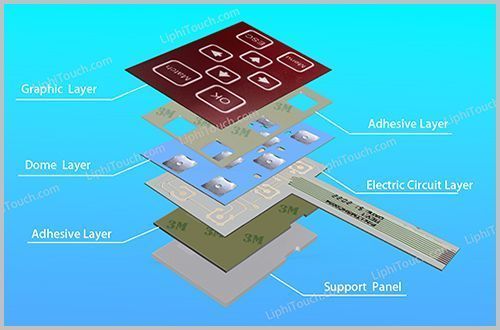

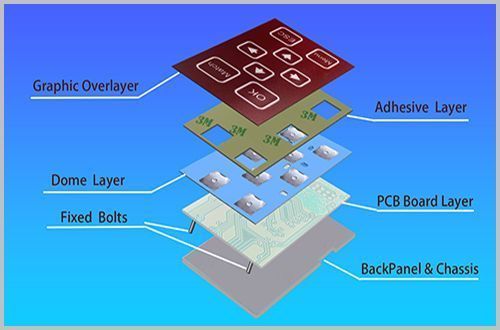

Firstly Let us to analyse the structure material of membrane switch, which is sandwiched or multi-layers.

General membrane switch has three layers or more. However, most membrane switches contain three to four layers, even to more. These various layers of a membrane switch can often be divided into a few fundamental categories.

Circuit Layer

A membrane switch’s circuit layers are the membrane switch control part, that contain button metal dome layer and printed circuit layer. Dome layer is positioned at uper level, pirnted circuit layer at lower one.

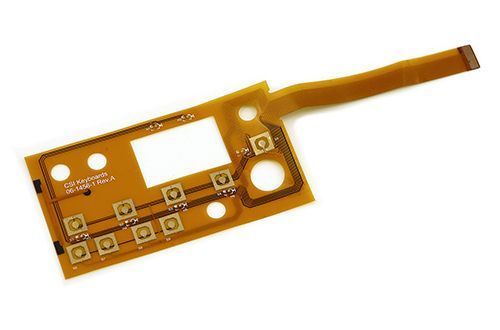

The circuitry in the circuit layers is devided into two types, Flexable FPC printed circuit sheet or Rigid copper embed PCB board. FPC print circuit is printed with metallic ink onto a polymer film (e.g., silver-based and carbon ink). A printed flexable circuit sheet (made of a material like ITO or PET) is used as the static or bottom layer. But PCB board is embed by many copper slips. It can be given the entire switch assembly structural rigidity and various mounting options (such as connectors for soldered parts).

Metal Domes Embed Layer

We often see all membrane switch by eyes, when you press its buttons, you can feel clearly it is elastic feeling. All of these ,decide all membrane switches. On which buttons , there should be a metal dome. These domes underneath each button respectively. So they are sealed by adhesive insulation layer, this is called as metal dome layer.

Various Insulation Adhesion Layers

Beside of the contact points between dome layer and circuit layer, balanced parts should be departed with insulatioln material avoid of short circuit occured. As circuit layer should be waterproof , anti-damp. Justly we also make some of custom shaped adhesive layers to meet these membrane switches’ special demands. These adhsion layer is insulated, a close circuit will complete when pressing down the dome key. By it can control various equipments and devices rightly.

Graphic Overlay

Since the actual buttons and user interface for operating the switch are located in the top layer of a membrane switch. This layer is frequently referred to as the graphic overlay. When graphic and icons are printed on polyester or polycarbonate film substrates. Polyester is frequently used because of its increased durability and improved resistance to chemical corrosion.

Membrane Switch’s Loss is tiny Less so it has a long life span

Membrane Switch’s loss is tiny less due to its lamination struction. In general, three parts, comprise of circuit part, adhesive insulation part and indication overlay part. Its circuit layer is control layer. When tactile dome layer contact to the printed circuit layer in a tiny time, trigger a pulse to close circuit and open to control machine and device running.

With our tactile dome pressing life span tesing, each dome is up to 50 millons times within its life span. In another one, the loss of between tactile dome and conductive ink on the printd circuit sheet is taken into consideration. At a moment, they contact with each other, can have a tiny fiction, makes less conductive ink fall off. Since many repeats in long time at same position, many losses is coming. Compare with those traditional mechanical switches, its advantage is obviously, It is convenience and safety, therefore, It has a long life span.