2 stages membrane silicone keypad manufacturer execute for creating best keypads?

Stage # 1:

Here we are describing you all the essential stages which membrane silicone keypad manufacturers carry out while designing a silicone keypad. All silicone keypads go under this intensive testing control in order to manufacture masterpieces for particular purposes.

Moreover, these vital steps are:

Deciding the tool:

First of all, membrane silicone keypad manufacturers decide to choose the best silicone molding machines for creating best silicone rubber keypads. They need a tiny less tolerance for molding products.

Best conductive pills:

They select some best quality silicone rubber for creating ideal keypads. Furthermore, for creating silicone rubber keypads, these manufacturers use carbon silicone pills. Because these are ideal and most popular to use in creating silicone rubber membrane keypads.

In another one, silicone rubber which is in the form of these conductive pills helps to make it a secure co-mold with such keypad together.

Mold for shaping the silicone rubber keypads:

membrane silicone keypad manufacturers place this special kind of gum stock silicone rubber on the selected tool. The pressure and heat in this tool can form this silicone in the layout of the mold tool.

Stage # 2:

- Keypad After the Molding Cycle

- Adding different attractive and useful colors

- Remove the keypad from the instrument or tool

- Screen printing

- Testing for properties

- Quality control

Keypad After the Molding Cycle:

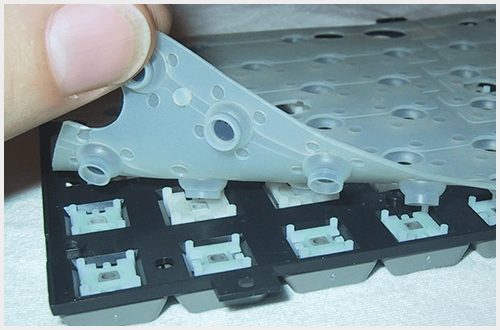

The keypad manufacturer maintain the heat and pressure till the selected material got the special shape. Then they open the mold tool and then remove the keypad sheets for the purpose of further additional processing.

Adding different attractive and useful colors:

In this step, membrane silicone keypad manufacturers add special colors for some special purposes. All the signs will get their specific colors while the remaining alphabets will remain same. Although they do it manually and blend silicone with colorful base. But you can only see the top of these keys via bezel.

Remove the keypad from the instrument or tool:

The operator use air hoses in order to remove the keypads from the mold tool. Moreover, the carbon pills which was used to place in the bottom of the mold tool. Because they want to mold the keypad and hence, they have got it now.

Screen printing:

The worker place a stencil over the keypad. The reason behind is to expose the key by receiving ink on this screen-printing pass. In fact, each color of screen print will use a stencil.

Testing for perfection:

After creating the rubber keypads, membrane silicone keypad manufacturers test in order to ensure their functionality. Basically, they test them to make sure that whether these keypads can meet the mechanical and dimensional tolerances of customers.

Quality control:

In the end, when the molding process has done and they got the desired keypads. These manufacturers check and inspect them for quality issues.

5 advantage of good membrane silicone keypad manufacturer

Here are some attentions which you should keep in mind while selecting a good keypad manufacturer. Actually, you should keep them in mind for getting the best quality products.

Hence, these are:

1. Reliable:

The good manufacturers of keypad should be reliable. So, you should confirm the quality of their products before getting their services.

2. Products Durability:

Always select the best membrane silicone keypad manufacturers which can provide you long-lasting and durable products. For example, your keypads should be of good quality and durable. Such as the manufacturer should give the guarantee of buttons for up to 1 million presses.

3. Budget Control:

The manufacturers of your rubber keypads have ability to provide you the best quality with low cost. Hence, you should contact the keypad manufacturers who will manage your full production even in low budget.

4. Best Quality Products:

Always keep in mind that your manufacturers of keypads should never compromise on the products’ quality. Additionally, they should always provide you the best quality products.

5. Delivery on Time:

membrane silicone keypad manufacturers which you select for making your keypads must have ability to deliver your products on time. Because in this era of technical race time is the most important factor behind every success. Your selected manufacturers of rubber keypads must be punctual.

In fact, the value of time is the basic key to success. Moreover, the best keypad manufacturers are those who can provide you best quality keypads on time. This is the only way to win the trust of their customers.