This article tell you how to choose the optimal membrane switch for your favorate user interface

WHAT IS A MEMBRANE SWITCH WITH PCBA?

A membrane switch with PCBA, just like an electrical switch, turns the circuit on and off. These controls are slightly different from standard mechanical switches; however, the principle is the same. When the two poles come in contact, the circuit closes, and the current flows. Nevertheless, membrane switches are advantageous because they are eco-friendly and security. Membrane switches have many different types,

- Tactile membrane switch

- Non-tactile membrane switches

- Mixed panels

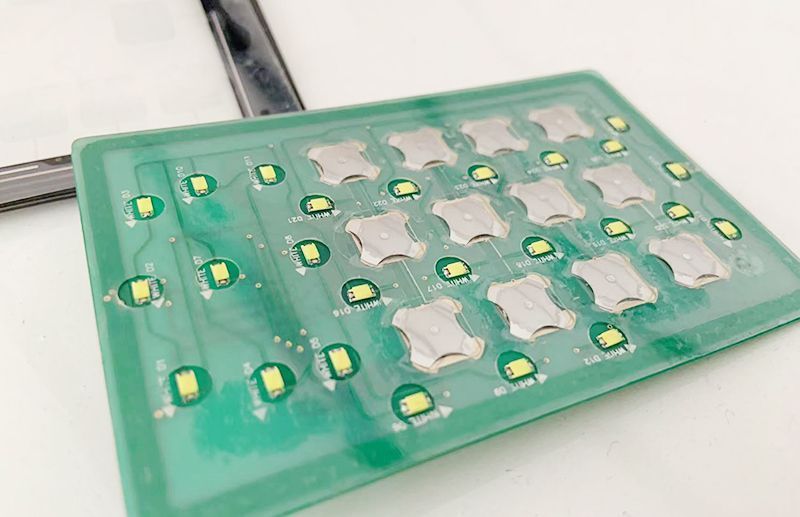

A flexiable printed circuit assembly or a PCBA membrane switch is membrane electrical switch that belongs to the mixed panel category. A diverse panel membrane switch is the combination of both tactile and non-tactile membrane switches.

what is PCBA?

Printed circuit board assembly (PCBA) is a specially designed integrated control system. So PCBA membrane switch, as the name implies, consists of a printed circuit board typically made of high conducting materials. The main reason is to offer less resistance to electricity current. Copper is the primary material commonly used in PCBA membrane switches.

What is the PCBA membrane switch made of?

Like a burger, the PCBA membrane switch has different layers one over another. I will tell you about the PCBA membrane switch structure to help you understand its function. The thickness of the PCB switch depends on the layers of the switch. A regular PCB assembly of the switch has the following layers,

· Resin Substate Panel:

This is the bottom layer of PCB, it can be used as backpanel for the membrane switch, all electric components will be fixed on it , even though a control electric circuit bulit. It is etched from the resin substrate coated with copper,shape into a control circuit. On which embed of chips, capacitor,diodes and triodes welded. This will structure a completed control system.

· Copper:

Copper is our conductor. It is an essential component of the PCBA membrane switch. We add a thin layer of copper foil to our board just below the solder mask. We can also add additional layers of copper according to our requirements. The layers can be single or double-sided. The maximum limit is 16 layers of copper foil. Copper layers can increase the thickness of the switch.

· Solder mask:

A solder mask layer is the second layer. It is just above the copper and below the silkscreen. The primary function of the solder mask is to insulate the copper layer. It covers the whole layer so that copper cannot accidentally come in contact with other metals. Moreover, it is the layer that gives green color to the switch.

· Adhesive Insulatioln Liners

About adhesive liners, they are is necessory, because they are insulative, can separate from two adjacent circuit layers, contact points left only so that the user can operate user interface easily. Also its another application , that is to have a strong adhesion, stick two differrent goods together tightly. Like this, have more sandwich layers structure. But also the rear side of PCB, maybe use adhesive layer to solid control panel on the device closely.

· Graphic overlay :

This is the top layer of the PCB assembly membrane switch just above the solder mask layer. This layer is visible to the naked eye. It has many instructions written on it for a better understanding of its use. We often label it with numbers and symbols to elaborate the function of each pin.