LuphiTouch is a Professional Membrane Switches and User Interface Control System Manufacturer

LuphiTouch is a professional membrane switch manufacturer in China, it provides a comprehensive list of membrane switches. They contain: PCB membrane switch, waterproof membrane switch, membrane switch panel, backlit membrane switch and rubber membrane switch etc.

The company was founded in 2008, so we have had 15 years of experience in membrane switch manufacture and User Interface (Human Machine Interface) control system.

2008 – we built VIT company in Hongkong.

2010 – VIT started the business about touchscreen and LCD.

2012 – Established Company in Chang’an Town, Dongguan City.

2014 – Bulit PCBA factory (1500 SQM) in Dongguan City.

2015 – Established a new high-level membrane switch factory—Dongguan LuPhi Electronics Technology Co., Ltd. (2000SQM).

2016 – Built 100-class anti-electrostatic precision electronics assembly clean room; introduced OCA lamination and defoaming machines; certified by ISO9001 and ISO13485.

2017 – PCBA factory introduced the 3rd SMT production line. Of course Membrane switch factories’ success in developing the capacitive touch and sliding membrane switches; PCBA factories’ sales turnover broke 4 million US dollars, and membrane switch factories’ turnover broke 3 million US dollars.

2018 – Certified by ISO14001 and OHSAS18001

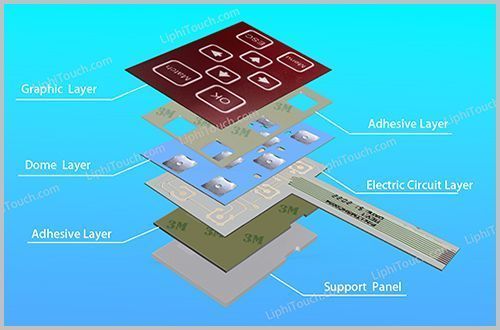

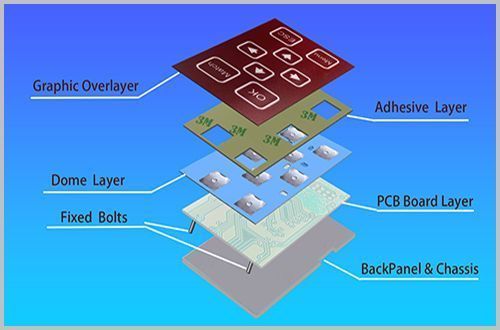

Membrane Switch’ Mutil-layers

As membrane switches have two layers or more. However, most membrane switches include three to four layers, if not more. The various layers of a membrane switch can often be divided into a few fundamental categories.

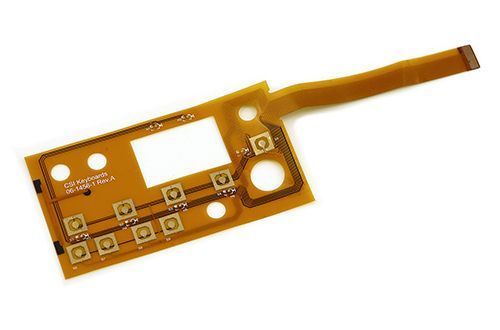

Circuit Layer

A membrane switch’s circuit layers are the membranes that contain electrically conductive material to complete the circuit. They are part of and positioned at the bottom of the assembly.

The circuitry in the circuit layers is devided into two types, Flexable FPC printed circuit sheet and Rigid copper embed PCB board . FPC print circuit is printed with metallic ink onto a polymer film (e.g., silver-based ink). A printed flexable circuit sheet (made of a material like ITO or PET) is used as the static or bottom layer. But PCB board is embed by many copper slips. It can be given the entire switch assembly structural rigidity and various mounting options (such as connectors for soldered parts).

Metal Domes Embed Layer

We often see all membrane switch by eyes, when you press its buttons, you can feel clearly it is elastic feeling. All of these ,decide all membrane switches, on which buttons , there should be a metal dome. These domes cover on each button respectively, then they are sealed by insulation layer, this is called as metal dome layer.

Graphic Overlay

Since the actual buttons and user interface for operating the switch are located in the top layer of a membrane switch, this layer is frequently referred to as the graphic overlay. When graphic and icons are printed on polyester or polycarbonate film substrates. (Polyester is frequently used because of its increased durability and improved resistance to chemical corrosion.)

There are numerous ways to create a graphic overlay. It is often printed or embossed and is visible from the membrane switch’s surface. It could be digitally printed or screen-printed with various colors and letters. The graphic overlay may also be covered with acetate film that has been photochemically patterned with buttons, which is more cost-effective and offers a wider variety and better quality of graphic effects. (In fact, digital printing is frequently favored due to these factors). Depending on the application’s needs, it can have varying degrees of heat resistance, impact resistance, abrasion resistance or corrosion resistance.

Why Choose LuphiTouch

As a membrane switches manufacturer, we have amassed a wealth of knowledge and experience that our clients have come to rely on when trying to design and achieve particular user interface goals. By customer’s requirements, we can accurately produce membrane switch panel,printing flexable electric circuit or embed copper into PCB board, making sealing and insulation treatment, assembly and testing at last.

Since there are so many variables to consider when designing membrane switches (such as circuit layer, the graphics overlays, adhesives and its application), we frequently consult with customer engineering teams early in their development process to ensure that their designs are feasible and produce the best results. learn more about it , Here Click !