The Box-build assembly or top-level assembly is a less defined matter

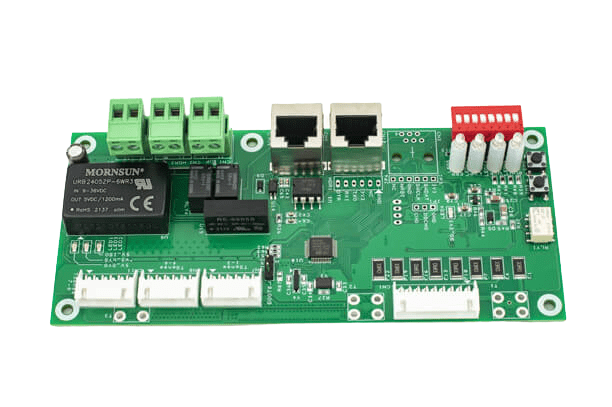

If you are thinking of outsourcing an electronic printed circuit board assembly (PCBA), It, therefore, is an obvious step that you are taking. On the other hand, lies an easy method where you can just simply hand over the records, a suitable software as CAD, and a bill of materials (BOM). After that, you are free to go to your favorite places. Box-build assembly on the other hand involves a process that is in the notice of everybody . One can say that the process is not well defined. It means that in a single box build assembly we can talk of many things. It may involve a PCBA in a small enclosure. Furthermore, it can need a large cabinet that is full of complex chips and an unimaginable flux of wirings. It nevertheless may contain a fully complex system of electro-mechanical machines and livers, with a variety of electronic components.

What Is a Box-Build Assembly?

If you are planning to build or outsource custom box-build assembly, you must know of some important matters. For the naïve and laymen sort of people, this type of assembly pageants general term for all kinds of assembly processes. Those processes involve various electronic designs and chains of manufacturers. This however doesn’t include the manufacturing of a printed circuit board. The system, in addition to that, is also referred to as something famous as the system integration process. It is because this box contains anything in it. Starting, hence, from a circuit board to the inclusion of highly complex electronic parts and components making it a fully integrated system. Read More

Advantage Of Using One Company for Box-Build Assembly And PCB

One of the most crucial and critical issues that the customers, as well as outsourcing firms, are facing whole box-build assembly process is assigning projects to different ends. Similarly, whilst outsourcing a project of PCB design we also tend to search for a different vendor. However, the thumb rule for this allows the customers to hire a single firm for both processes to eliminate the chances of errors. It is reason that you are trusting a single firm for a whole project.  Furthermore, between communication process between companies and the customer becomes more complex and hectic. It always remains limited. Consequently, making the companies let the project remain incomplete. This feature also becomes responsible for severely damaging the Printed Circuit Board while manufacturing it. On the other hand, lies the idea to outsource a single company for both projects. This step helps to evolve the dead system thereby allowing to flourish the cost-effective method. It is because one eventually has to eliminate the need to hastily transport the order from two different companies. With single vendor one cans be sure of as it is the quickest the efficient most method.

Furthermore, between communication process between companies and the customer becomes more complex and hectic. It always remains limited. Consequently, making the companies let the project remain incomplete. This feature also becomes responsible for severely damaging the Printed Circuit Board while manufacturing it. On the other hand, lies the idea to outsource a single company for both projects. This step helps to evolve the dead system thereby allowing to flourish the cost-effective method. It is because one eventually has to eliminate the need to hastily transport the order from two different companies. With single vendor one cans be sure of as it is the quickest the efficient most method.

How Box-Build Assembly Is Helpful for Manufacturing Reliable Products?

It is a noted and time-tested at maximum that turnkey product tends to appear as more reliable and durable than the other. Box-build assembly is the best example. This is because at first, it comes off from a single manufacturer rather than multiple vendors. Also, an experienced vendor always uses a prototype as a model which is easy to test and implement. It helps in finding the flaws and errors before finalizing the mass production phase. It also eliminates the disappointment and resentment from customers if it gets defected. Furthermore, if we find flaws in the system, the manufacturing companies are bound to look at both the PCB and box-build assembly. Whereas, the separate vendor uses to always complaining about the other vendor rather than eliminating the flaw or issue. Therefore, outsourcing the project thereby promises the confidence that you build in the result. The product, in the end, brings more accuracy and efficiency.

Box-Build Assembly Services

There are a variety of things involve in box-build assembly services. The most pertinent of them are:

- Electric Components Sourcing

- Box or cabinet Design and Machining

- PCB Assembly and Box- build Enclosure

- System Running Programme Compile

- Testing and Adjustment

- Labeling and Packaging

- Hand to customer

Things To Remember for Box-Build Assembly

Following are the factors that one must keep in mind if any one is planning a box-build assembly. This information is also available with you.

Bill of Material

For any recognizable EMS provider, the consideration of the Bill of Material is of utmost importance. the following step tends to helps them by providing them with an idea of all the key components. It also mentioned the required material for your model by the EMS provider. The billing also explains use what will be offered to us free of cost. Furthermore, one needs to mention which of the product are small comprising the tie-knots, nuts, and bolts, etc. The same principle is applicable in differentiating the flux of wires with their different wire identifiers.

Visual File for Assembly

If it seems feasible for the customer, he or she must go for a 3D CAD model. The software is so effective that it helps to visualize the final product way ahead of the final product. in addition to this, several CAD packages offer free product reviews. There, however, are also other CAD models that are capable to carry options from converting visual to building construction.

Sample Unit

Sample units of box-build assembly always appear to be so much promising in terms of helping the customer. This sample can act as the key source if the drawings remain unfinished. However, on your urgent request, they can build and create a prototype design for your satisfaction. This guaranteed gesture makes things both satisfactory and reliable for customers.

Role of Dimensions

The size and weight of the box-build assembly are of very importance. That is because the experts are of the opine that one must contact the EMS provider about the size and dimension of your product. The following information is correct and helpful in many cases. One of such issues is shipping while the other step is storing. Hence, roles of dimension are integral and critical.

Testing And Adjustment

In case your box-build assembly involves electrical or high-tech electronic components you must look for them it’s maiden testing. The testing involves two major tests as earth bonding and flash testing. So, are you willing to perform these tests as in recommendations?