Through the analysis of the key components of the FPC thin film key switch

Through the analysis of the key parts of the FPC thin film switch, it is pointed out that the elastic plate of the protruding button of the thin film switch panel must be placed correctly without any deviation, otherwise it will affect the work of the key and lead to failure. Color Problem: Ink modulation ratio, is the main reason for color deviation, and the color requirements are too strict. Color Range is too small, these are indispensable factors, no matter in any industry is more difficult to control the problem. From the enterprise’s control cost, to the color range is very small, the cost is very high, the product cost will rise, the product unit price will also rise correspondingly, the customer can not afford, so. The range of colors should be within a reasonable range. , Button Position Drum bag, need to open the mold to a suitable position, otherwise it will affect the button aesthetic. Non-stick, in addition to the choice of raw materials, but also to ensure that the prototype looks good. If the prototype has grooves, you need to choose high quality glue. Just pick the right gasket.Membrane panel switch features

(1) good durability, membrane panel switch life can generally reach more than 100 million times, so long service life, because the switch action can only be completed through the elastic membrane vertical movement. The elastic thin film has experienced 1 million times of creep, but because the creep range is very small, only 0.1 ~ 0.3 mm (switch stroke) , the material selection is reasonable, far from reaching the limit of the thin film, therefore, thin-film materials can withstand more than a million lifetimes without deformation. On the other hand, the switch contacts are vertical and wear-resistant, while the screen printed contacts can be thick enough and printed with a layer of conductive carbon on the silver paste contacts to achieve high wear resistance and self-lubrication, the lifetime of Membrane switches is tens of times longer than that of mechanical contact switches.

(2) because of the integral sealing structure of the diaphragm switch, the switch contact is not corroded by harmful gas, is not easy to oxidize, is waterproof and dustproof, is more suitable for all kinds of bad environment, and has good sealing performance.

(3) a compact, lightweight, and rugged membrane panel switch can be assembled into a high-density membrane keyboard, which is a sealed membrane structure consisting of multiple layers of film. The connecting wires and conductors between the switches are completed at one time, the total thickness is 1 ~ 3mm, which reduces the volume, reduces the mass and improves the reliability. Color Rich, beautiful appearance, membrane panel switch according to the user’s design concept in the color design of personality, decorative effect in the performance of beautiful materials, decorative beauty, beautiful process features.

(4) in order to reduce the cost of mechanical and electrical products, traditional mechanical switches need to be welded during installation, even with fixed support. The membrane panel switch is installed as a stick type, only need to peel off the backing paper and stick it firmly on the outside of the machine. The circuit socket can be connected after inserting into the machine socket. Save manpower, save material, reduce the cost of the whole machine.

Parameter reference (based on the actual product):

| brand | LuPhi/LuphiTouch | Processing customization | yes |

| Key lifespan | ≥ 1 million times | Rebound time | 6ms |

| working voltage | <35V (DC) | Working current | ≤ 100mA |

| contact resistance | 0.5~10 Ω | Working resistance | 40 Ω~500 Ω |

| insulation resistance | >100M Ω 250V DC | Substrate pressure resistance | 2kDVC |

| working temperature | -25 ℃~+80 ℃ | Atmospheric pressure | 86~106kPa |

| Waterproof technology | IP65-IP67 | LGF/LED/EL | Support customization |

| Product Certification | ISO9001:2015 | Applicable scope | Medical equipment, industrial control, transportation, instrumentation, household appliances, electronic entertainment, testing equipment, communication equipment |

| type | Membrane switch | Using Materials | PC/PET/PVC/Acrylic/Anti static |

| 3C rated voltage range | 440V and below | Protective function | Waterproof and anti-static |

| Monthly production capacity | 2000000PCS | Product process | screen printing |

MEMBRANE-SWITCHES-TOTAL-SOLUTIONS

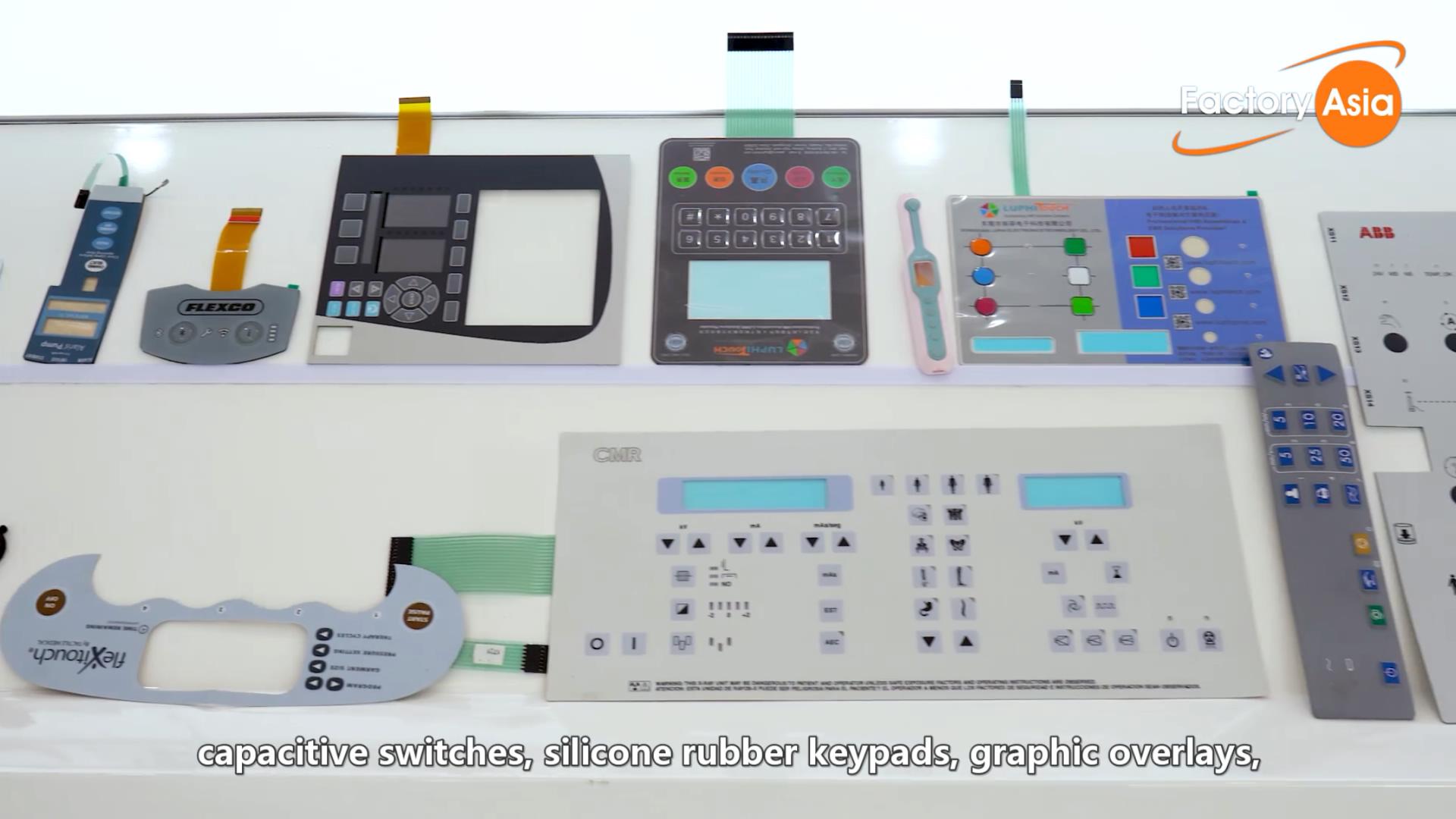

LuPhiTech,a professional OEM manufacturer of user interface subassembly products.LuPhiTech is located in south of China in Dongguan,and since 2008 the core of its business is manufacturing an export of membrane switches & keypads, capacitive switches, silicone Rubbert keypads, graphic overlays, and touchscreen panels. Besides,they also offer mechanical design and PCBA development, as well as development of single-chip solutions, keypad backlighting, and turnkey assembly.

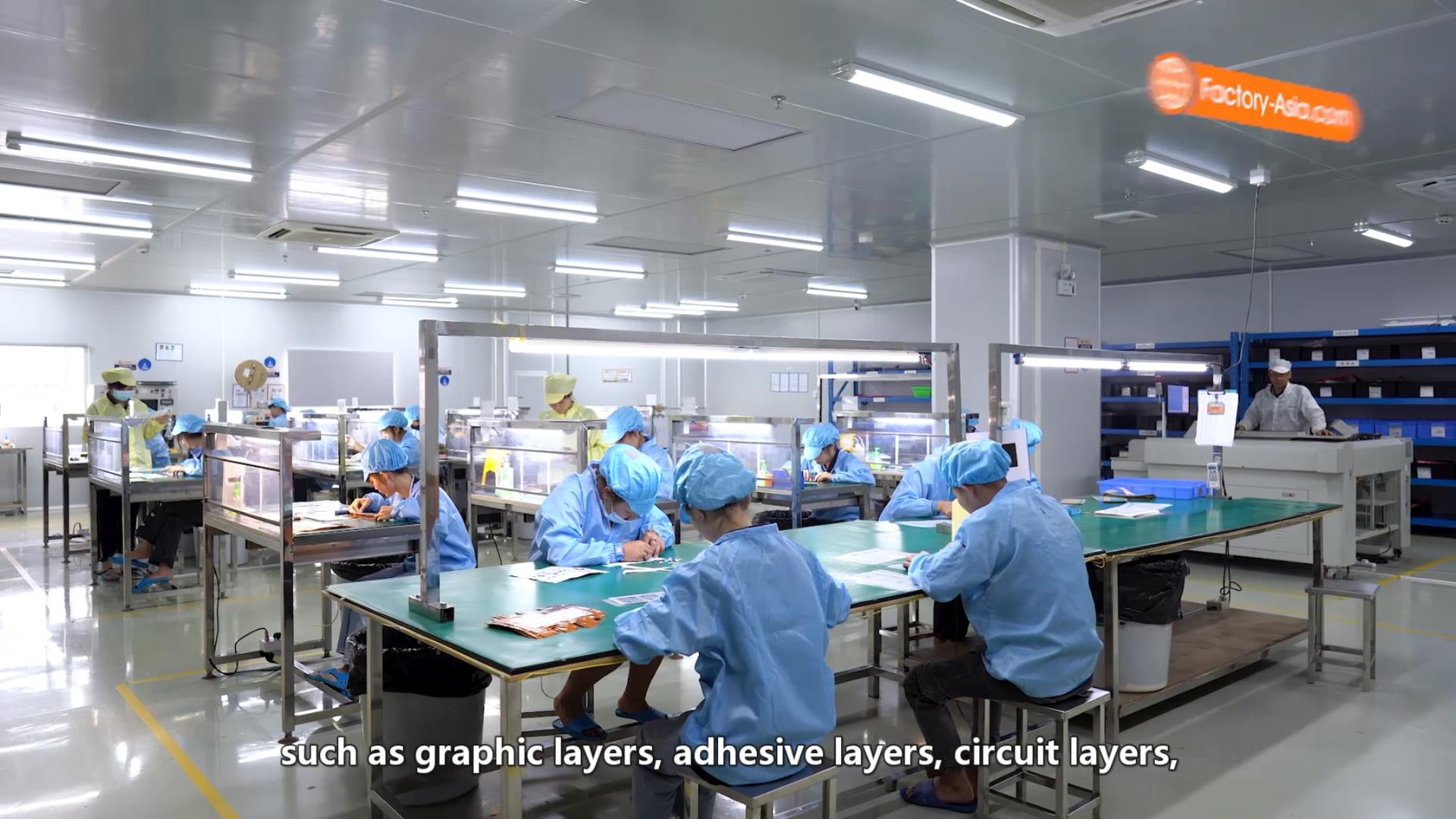

The production of high-tech interface products requires clean and well functioning operations.let’s get to know that how LuPhi complies with industry requirements.

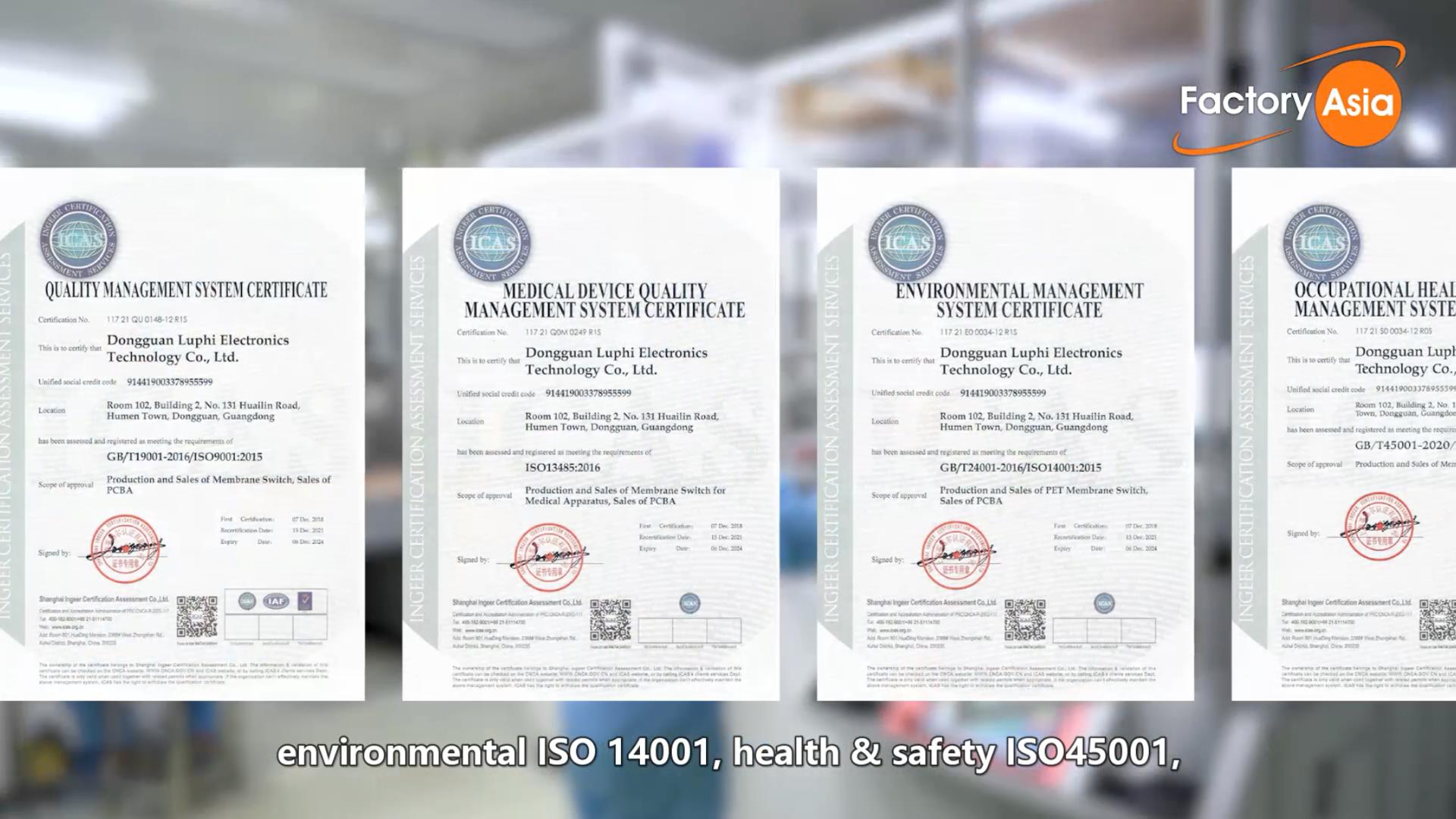

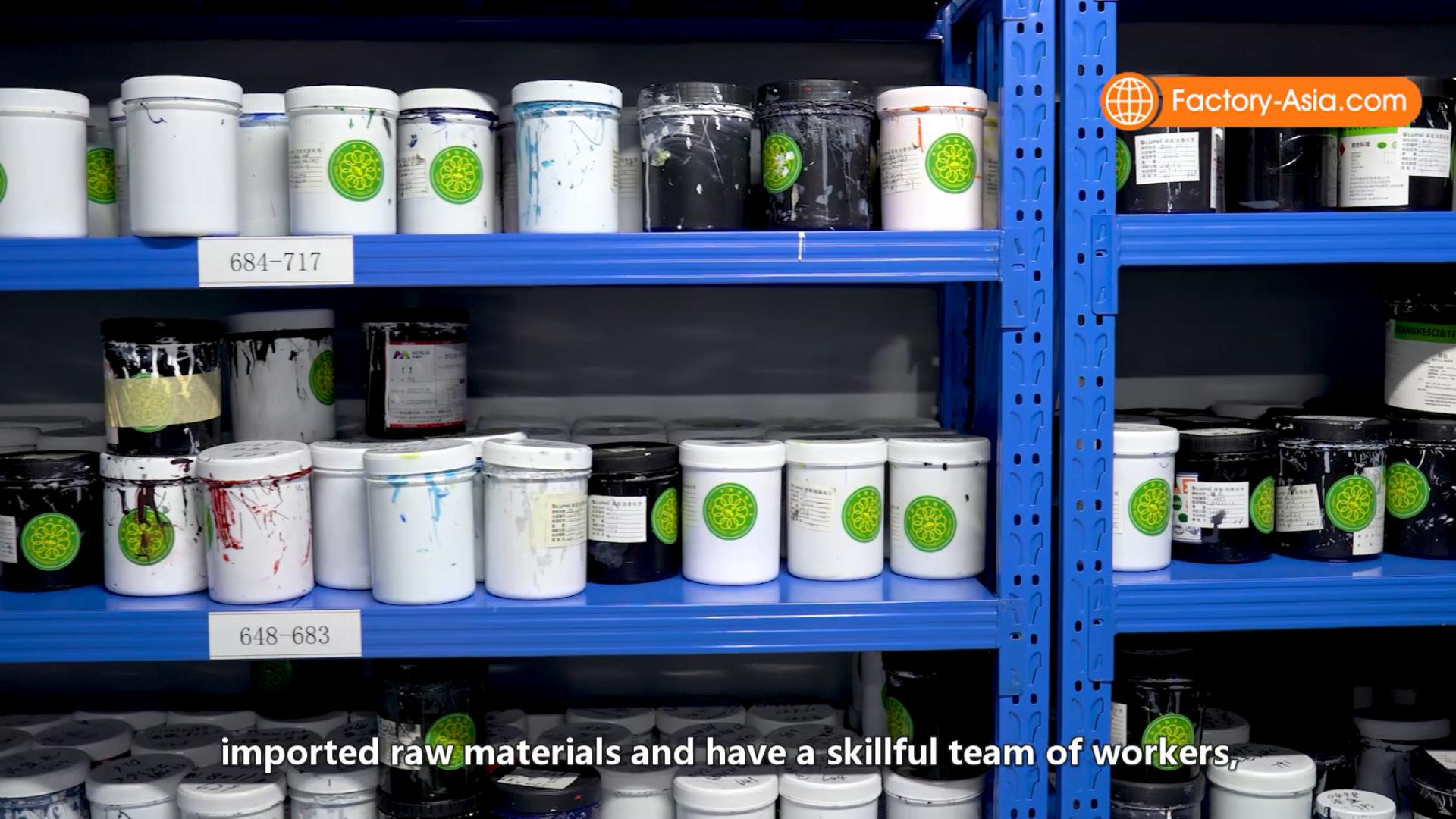

The factory has many strengths-we use high quality imported raw materials and have a skillful team of workers,as well as modern production and testing equipment,our facility is certified with ISO 9001,medical ISO13485,environmental ISO14001,health and safety ISO45001, and the production areas are equipped with 10000 and 1000 class cleanrooms.our products obtain main quality certificates for major markets, such as Europe,North America and Australia.

let’s go to the workshops to see how the products are made!

Design: First,the product concept takes shape in the R&D department,where LuPhi’s engineers design and create initial samples.

before mass production,their PP samples will undergo various function and environmental testing, such as button actuation life testing,high-low temperature constant temperature,and humidity testing,as well as salt-spray & waterproof testing,ink adhesion force testing,click ratio test, and many others.

01 KEY PROCESS OF PRODUCTION

Once the pre-production samples pass all necessary testing and materials arrive at the factory,production begins.LuPhi uses high-quality imported materials, such as 3M adhesive,Autotex polyester,nikomatic connectors, and many other components.

Material Cutting:

The first step of production starts from raw material cutting- where overlay films,circuit films and adhesive layers are cut by automatic cutting machines with high accuracy.

After that,the cut materials are transferred to a silk screen printing workshop,where first the ink is prepared to match the exact color requirements of the customer, and silkscreens are created for printing.

Silkscreen Printing:

Then films and screens are moved to automatic and semi-automatic silk screen printing machines.

Drying:

Following the printing,semi-finished products,are further passed to a baking treatment in a 12-meter drying tunnel until the ink is completely dried and cured, LuPhi also has 4 drying ovens to increase efficiency at this step.

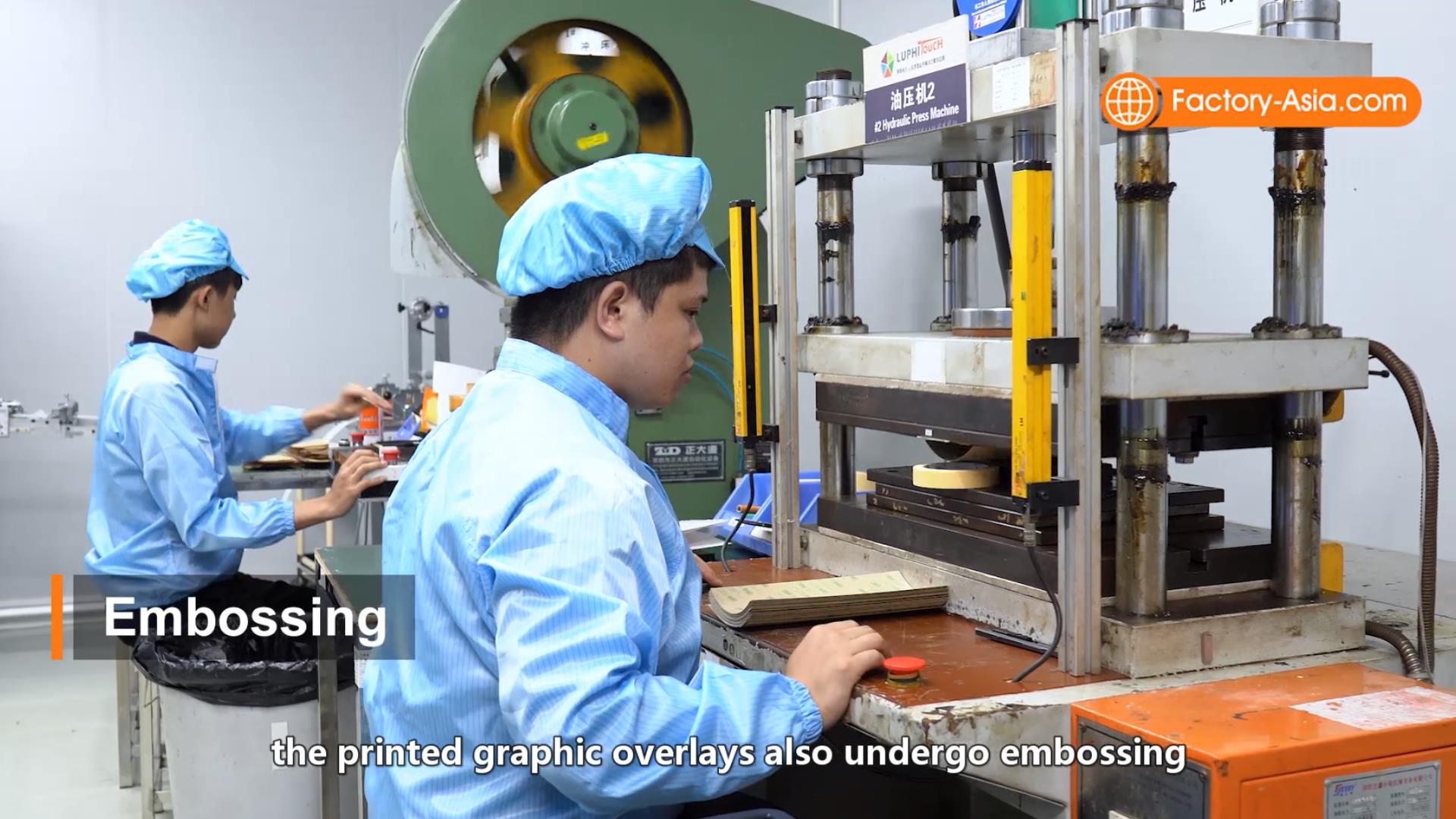

Embossing:

For many membrane switches with embossed buttons,the printed graphic overlays also undergo embossing in semi-automatic embossing machines.

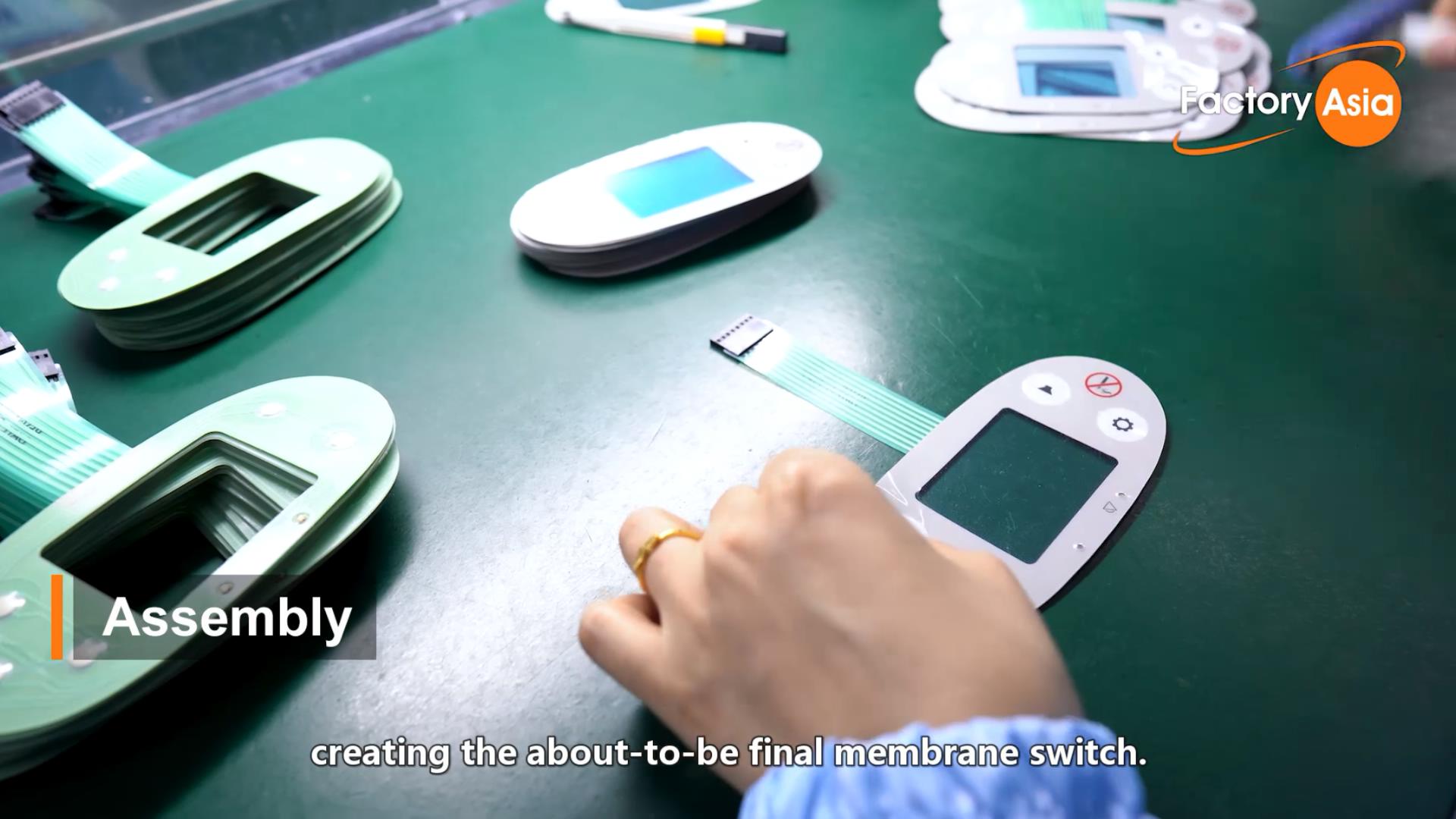

Assembly:

In the end, all layers of the final products, such as graphic layers, adhesive layers, circuit layers and others are assembled and laminated together, creating the about-to-be final membrane switch.

Punching:

After assembly,products are passed to auto die cutting&high accuracy cutting machines to cut out the membrane switch panels and form the final product shape.

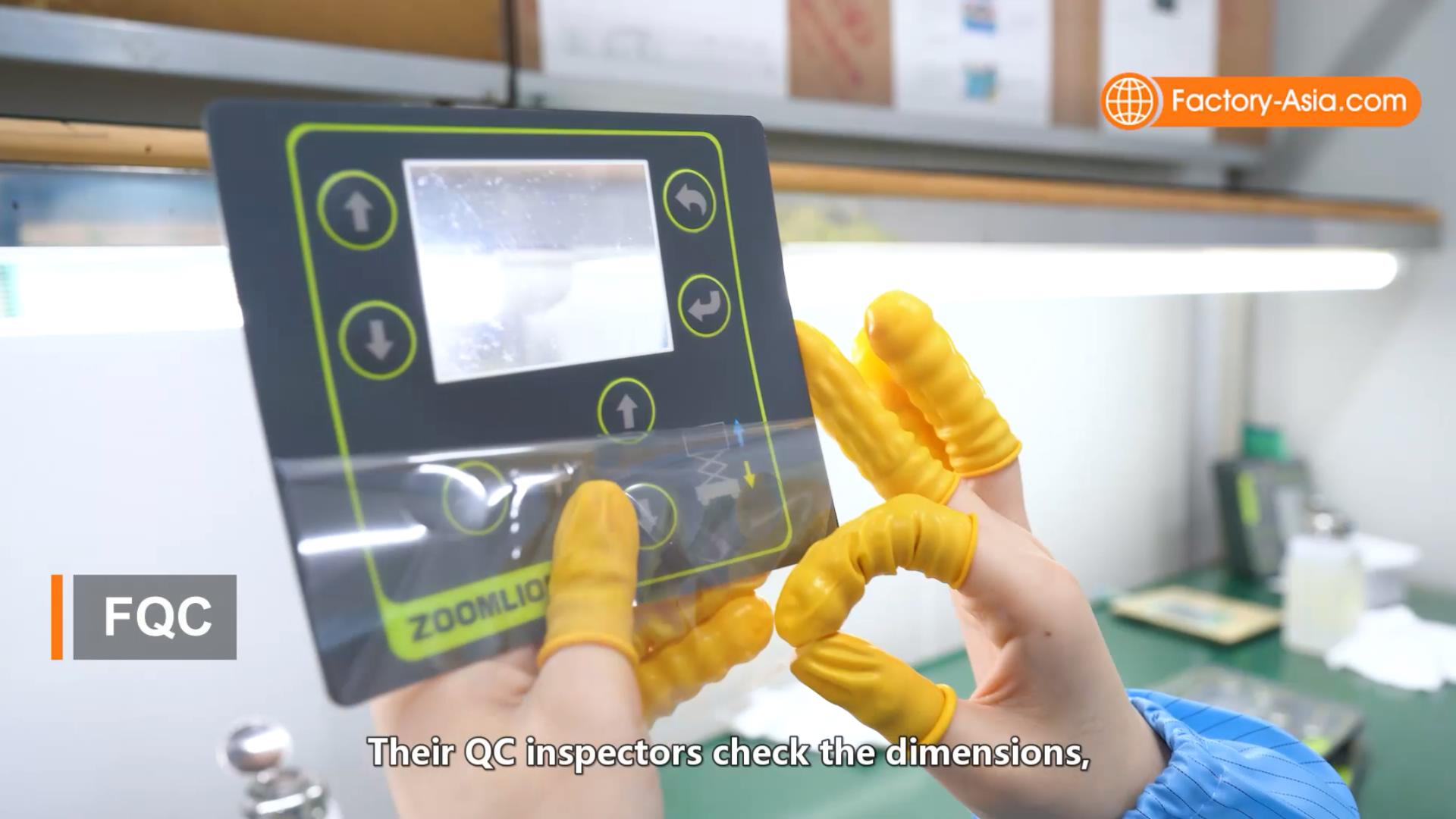

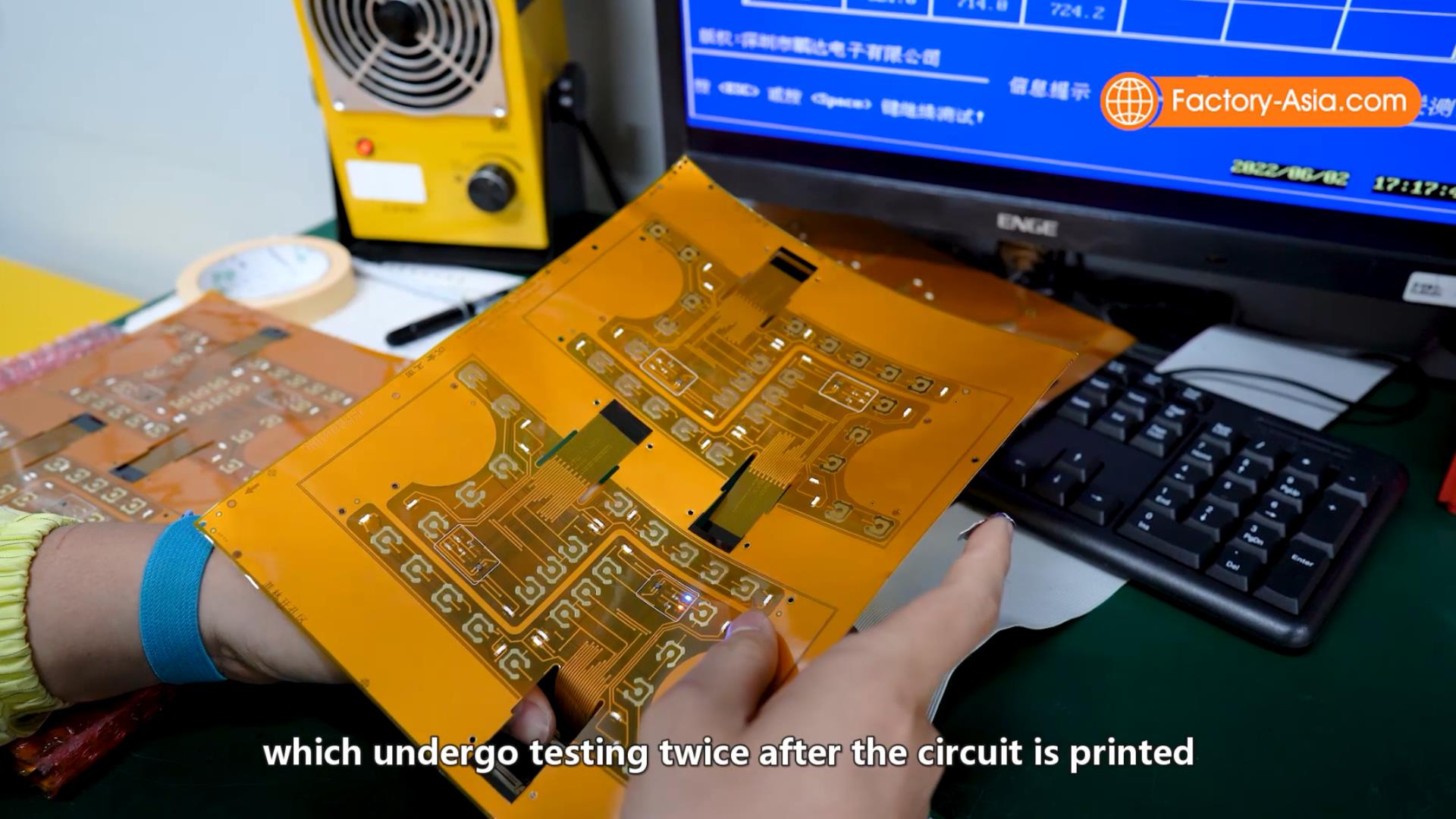

FQC:

At each production step,products are fully inspected with 100% appearance and function check, to ensure that every product received by customers is qualified.

Our QC inspectors check the dimensions, printings, workmanship and electrical functions, which undergo testing twice after the circuit is printed and assembly is finished.

Packing: Once products pass the inspection, they’ll be cleaned, packed into inner and expert packaging, and shipped to customers all over the world.

02 COMPANY DEVELOPMENT

With our team, about our history and recent achievements:Luphi was established in 2008 for production of human interface products. to support customers from various industries, including automotive, industrial,medical&healthcare industry, household appliances, and others.

over the past year, we achieve a 40% increase in sales through the concerted efforts of the whole team.At the same time, we have straightened the corporate culture, further improve employee satisfaction and happiness index,enhance team cohesion,and laid a solid foundation for the future performance growth.

How are we planning to support the strong demand at the market, in the next couple of years?To support the market demand in customer’s needs,in the next 5 to 10 years,we will increase investment into research and development, and will develop user interface modules for a variety of coffee machines, mixers, vending machines,juicers and other small household appliances.

At the same time,we will continue to strengthen the development and customization ability in high-end application fields,and achieve standardization in middle and low-end needs and customization of high-end needs.

03FACTORY AUDIT, SUMMARY

Now, end of tour to LuPhiTech, These have several advantages of the factory-our facility follows : ISO9001, medical ISO13485,environmental ISO14001, health & safety ISO 45001, and production areas are equipped with 10000 class and 1000 class cleanrooms, that guarantees a clean environment for manufacturing.

Moreover, LuPhiTech uses high-quality imported raw materials and can support the production of quality membrane switches and touchscreen panels in variety of sizes,designs,and functions.Besides that LuPhiTech have a mature quality control system for monitoring in-line and final product quality, with various appearance and function testing.