What does the production material of film face plate have, what does the material that produces film face plate have?

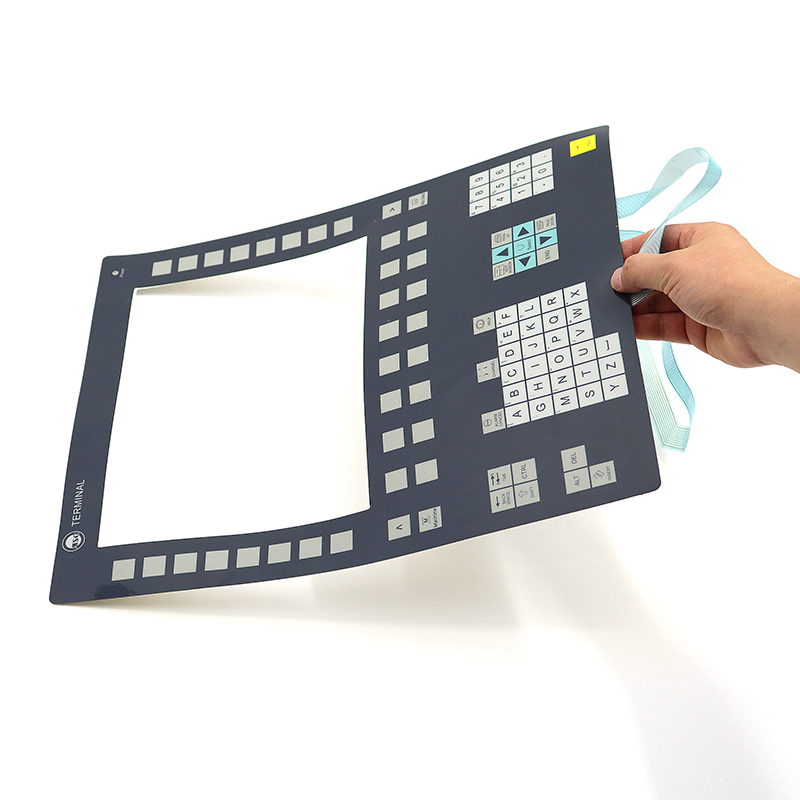

What does the production material of film face plate have, what does the material that produces film face plate have? Today, the editor will show you. 1. Sand polyester smooth surface wear resistance, insoluble in general organic solvents, not resistant to Alkali. With excellent mechanical properties, electrical properties, rigidity, hardness and thermoplastic, strength and toughness in the mouth, low water absorption, wear resistance, friction, dimensional stability. Tensile strength can be comparable to aluminum film, much higher than PC, PVC. Low cost because the surface is difficult to process into a sub-gloss, so for more expensive pet texture, is the production of thin film panel switch circuit ideal material. Textured pet is suitable for products with high surface requirements or liquid crystal display windows. Figure 2. Polycarbonate has high light transmittance, low water absorption, good dimensional stability, excellent bending, tensile, compressive strength, heat resistance, cold resistance, electrical insulation and atmospheric aging resistance. Poor drug resistance, poor fatigue resistance, easy to produce stress cracking, the output circuit is generally printed with carbon materials, and there is no protective layer, air oxidation gradually formed a layer of spalling, leading to circuit open and end of life, this means that membrane panel switches are more prone to failure, mainly due to the environment, whether used or not, the physical damage time is 3-10 years. Generally speaking, it can be widely used.

In addition to meeting the requirements of most thin film switch panels, PCs high transmittance can also meet the requirements of LCD windows. Line Printing Material: The printed circuit board is made of Polyethylene terephthalate (PET) film. With good insulation and heat resistance, mechanical strength, transparency and air tightness, especially flexibility and elasticity, it is an ideal material for making thin film switch circuit. Polyvinyl chloride is stable to acids, bases, and salts at room temperature. Good wear resistance, self-extinguishing, noise and vibration elimination, good electrical insulation performance. Poor thermal stability. Low cost generic logo, panel.