An Introduction to rubber silicone keypad

Custom membrane rubber keypads are made of the silicon rubber material. The silicon rubber is a non-toxic and elastic material. These silicon rubber keypads pass through the processing with the help of compression method or injection molding.

After processing, these silicon rubber materials integrate with the switch components of the printed circuit boards. This process of integration produces a universal human machine interface (HMI).

We provide you with the best production quality of the custom rubber keypads. We can also provide samples and prototypes for your designs.

Custom rubber membrane keypads Applications

There are many industrial and commercial applications of custom membrane rubber keypads. These include the security systems, the hand held electronics, remote controls of the devices and so on. These custom keypads offer following advantages at the industrial and commercial scale:

They are best and effective at developing and enhancing the human machine interface. The reason is that they provide the tactile feel to the end user in an excellent way. Moreover, they are much light weight.

They are not vulnerable to the harsh conditions. That is why they have a long life in the operation and processes. They are the reliable keypads as compared to the others for the industrial and commercial use.

If you need the keypads which have a long and steady operational life, then custom rubber keypads are the best choice.

Custom rubber keypads Properties

The outstanding property of the custom rubber keypads is that they are stable to the extreme conditions of the temperature and heat. They don’t lose working at the high range of the temperature and heat.

These keypads have the specific property of absorbing the shock and vibrations. They don’t malfunction with the high echo of vibrations and shocks. Moreover, these keypads are water resistant. They are not vulnerable to the water and other fluids.

On the other hand, the custom membrane rubber keypads are the economic and low cost choice for commercial and industrial use. They are less expensive as compared to the other keypads like mechanical switches. Moreover, many other keypads like dome switch keypads are also expensive than the custom keypads.

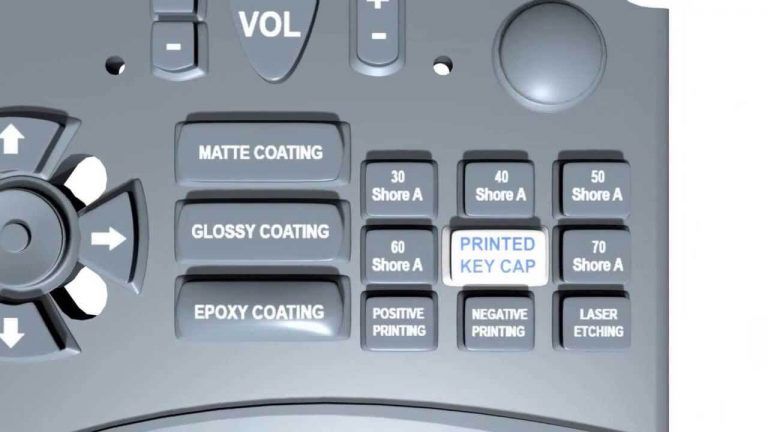

The custom keypads are the type of keypads whose tooling is very easy as well as economic. It makes them the less expensive keypads in the industrial and commercial use. The most astounding property of the custom rubber keypads is the flexibility of their design.

The keys of these rubber keypads are able to mold according to the requirement and specification of the customers.

Custom rubber membrane keypads Design Process

The design of these rubber keypads has certain steps and is according to the given arrangements. First of all, the purpose of the design and its function is the thing that is to clear at the initial step.

The mechanical engineers have years of experience in the manufacturing of the designs of the rubber keypads. The certain steps of the design of custom keypads are as follows:

The illustrated and complete drawing of the product is available and approachable. If the drawing of the product is not available, then the facility of replication is available. By using a sample part of the drawing of product, the complete drawing is easy to fabricate using replication.

In the case, you don’t have the drawing as well as the sample part of the drawing, don’t worry. The solution is still there by different steps.

Tactile Characteristics of Custom rubber membrane keypads

Once we have determined the visual and functional characteristics of the custom rubber keypads, the tactile properties are important. During the design formation of the custom rubber keypads, the most important thing to consider is the tactile feel.

The tactile feedback and feel of the custom keypads are the fundamental user assistant features of the keypads. The user love and like this feature of these keypads.

In the tactile feedback and feel, there is a tangible response to the user. When the user depresses key on the custom keypad, there is a tangible and physical feel that the user feels. The types of the tactile feel on the custom keypads are of the five categories. These are cone, double cone, bell, double bell and flat.

This tactile feedback of the custom keypads is an important distinguishing character of the keypads. This tactile feel of the custom rubber keypads is able to modify and customize with respect to the requirements of the customers.

This is a complex process and has many actuation steps on the way. These steps are important in the improvement and enhancement of the tactile feel. Some of these steps are contact force, actuation force, and key travel and return force.

Rubber Membrane Keypads Benefits and Uses

Custom rubber keypads have a variety of benefits and user in every walk of life. Then reason is that they have the ability to mould and modify according to the given requirement. That is why they have wide range of use in the many fields from medical to electronics industry.

The fundamental difference between the custom rubber membrane keypads and other types of keypads is that they are made by the compression molding. When the user presses a key on the keypad the compression pushes down to produce the tactile feel. Similarly, when the user releases the key, it comes to its original shape again.

As the custom keypads are able to modify, they have much more reliability and durability than other keypads. They can bear the harsh environments from the hospital and medical conditions to the dusty conditions of constructions.

Conclusion

They have wide range of applications in many commercial and industrial areas. They are a part of devices in the medical industry to inculcate the tactile feel. In the area of control system, they are the part of many appliances and equipment controls. In the field of electronic components, the custom rubber keypads are an important part of the computer hardware and peripherals.

On the commercial scale, many appliances and devices use the custom rubber membrane keypads. The commercial use of these keypads is due to the flexibility and durability of the keypads. Moreover, they are resistant to the dust and dirt produced in the commercial areas. They don’t get damage and malfunction due to this dirt and dust.